Presse

12/02/2026 - Oliver Hagenlocher - Presse

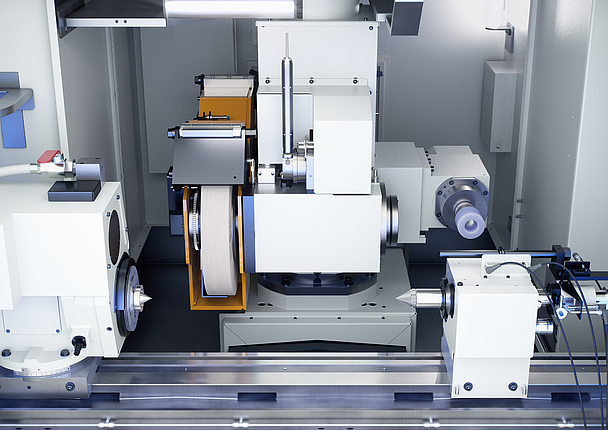

EMAG UG Series - Universal grinding machines for precision manufacturing tasksThe universal grinding machines in the UG Series combine proven grinding technology with a cost-efficient machine base. They are ideal for users who are looking for a sophisticated solution for internal, external and out-of-round grinding and do not want to compromise flexibility, precision and…

29/01/2026 - Oliver Hagenlocher - Témoignages clients

Le Retrofit comme approche stratégique dans la fabrication : VSC 400 DDS dans la fabrication en petite série d'engrenages de précision chez EWS WeigeleLe rétrofit des machines est souvent considéré comme une solution de secours - un compromis entre un budget limité et le souhait de disposer d'une technique de fabrication moderne. L'entreprise EWS Weigele GmbH & Co. KG d'Uhingen montre toutefois que cette vision des choses est insuffisante. En…

14/11/2025 - Presse

VSC 500 et VSC 500 DUO d'EMAG : Perfectionner les processus de tournage sur des composants de camions de poids conséquent et de grande tailleLe marché des véhicules utilitaires est à la veille de grands changements : Les propulsions électriques à batterie et à hydrogène devraient prendre le relais dans quelques années et remplacer partiellement le véhicule à combustion classique, selon le souhait des politiques. Mais pour cela, les…

01/10/2025 - Oliver Hagenlocher - Témoignages clients

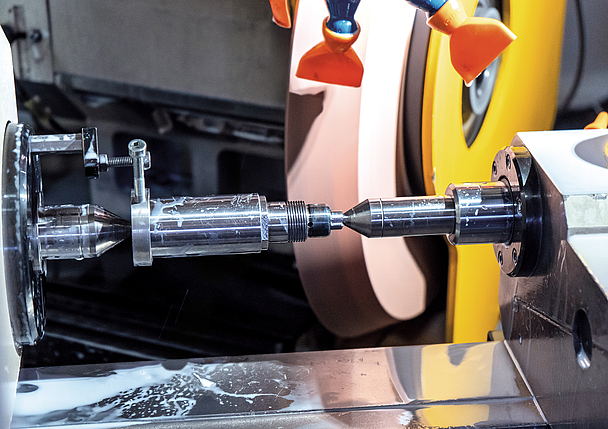

Rectifieuse compacte à plongée oblique améliore les processus de productionAu cours des 50 dernières années, Wandel CNC-Technik GmbH est devenue une entreprise de sous-traitance bien établie avec son propre portefeuille de produits. L'entreprise familiale Swabe, aujourd'hui dirigée par la deuxième génération, a continuellement élargi sa gamme de fabrication : du fraisage à…

01/09/2025 - Oliver Hagenlocher - Presse

WPG 7 d'EMAG Weiss : Assurer des process de rectifications extérieures rapides dans une implantation réduiteDans de nombreux domaines d'application, il n'est pas économique d'utiliser des rectifieuses cylindriques universelles surdimensionnées pour l'usinage extérieur de pièces plutôt petites - on perd ainsi beaucoup de place, sans pour autant exploiter la fonctionnalité. Avec sa nouvelle rectifieuse…

08/08/2025 - Oliver Hagenlocher - Presse

MSC 5 DUO : centre de tournage CNC à chargement frontal pour du tournage soft et économiqueDans le monde de la fabrication d'aujourd'hui, les entreprises de production sont confrontées à des défis majeurs : pression croissante sur les coûts, pénurie de main-d'œuvre qualifiée et augmentation des coûts énergétiques. Cette combinaison exige des machines-outils qui génèrent plus de rendement…

30/06/2025 - Oliver Hagenlocher - Presse

VLC 450 DG d'EMAG : Perfectionner le disque de frein revêtu pour voiture lors du processus de rectificationLe disque de frein de voiture de l'avenir est revêtu - c'est la seule façon d'atteindre les valeurs limites strictes de la norme Euro 7 en matière d’émission de particules fines. De plus, plus la surface de freinage est protégée contre la corrosion et résistante à l'usure. Mais quel processus…

28/05/2025 - Oliver Hagenlocher - Témoignages clients

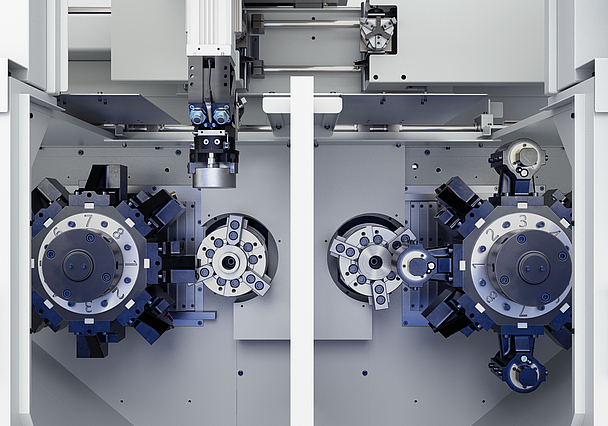

Compétence globale en matière d'usinage : les systèmes de machines EMAG VL dans la chaîne de fabrication de PENN GmbHLa complexité croissante des exigences dans l‘usinage des métaux et la pression internationale sur les coûts placent les entreprises de production des pays à hauts salaires devant des défis particuliers. L'entreprise autrichienne PENN GmbH s'est établie en tant que transformateur de métaux agissant…

07/03/2025 - Oliver Hagenlocher - Presse

Revêtement de disques de frein par soudage par dépôt laser : Revêtement efficace des disques de frein - et respect des directives EURO 7La norme EURO-7 va modifier massivement la construction automobile : Pour la première fois, non seulement les émissions des moteurs à combustion, mais aussi, entre autres, l'abrasion des freins seront réglementées. Première conclusion : les poussières fines qui apparaissent doivent nettement…

19/11/2024 - Oliver Hagenlocher - Témoignages clients

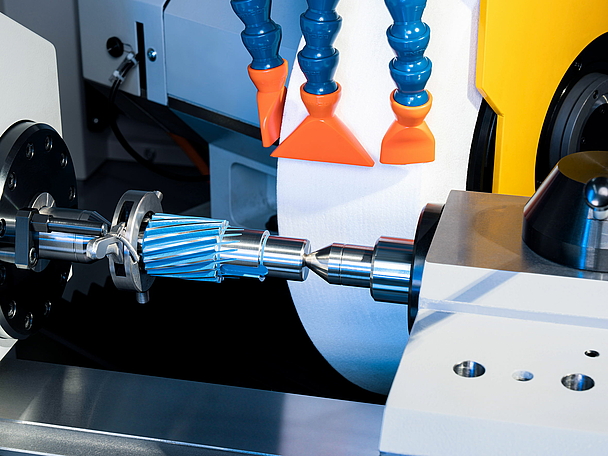

Precision manufacturing of high performance transmission components on vertical pick-up turning machinesZoerkler Gears GmbH & Co KG, a renowned manufacturer of high-precision drive systems for the aerospace and automotive industries, is using the VL 6 vertical pick-up turning machine from EMAG for machining high-precision transmission components. This strategic investment underlines Zoerkler's…