Lathes for the Flexible Machining of Flanges

“Downsizing” remains the focus of industrial production, in regards to car engines, in the energy industry or also general mechanical engineering. Ever smaller and more precise components are being produced, such as flanges. EMAG's VL-series lathes provide an effective solution to these special production tasks.

Complete Machining of Flanges

The design of the new VL vertical turning machines make it possible to apply different production technologies for soft and hard machining.

It is also easy to link several of the lathes; automation of the line is tailored to the customers’ requirements using "automation modules." This high degree of flexibility is the basis for success when machining a wide range of flanges.

Highly-productive manufacturing systems

Highly-productive manufacturing systems for flanges require top-precision lathes. With its VL series, EMAG provides the right lathes for turning these components economically. The EMAG VL 2 lathe is perfectly designed for the high-precision production of flanges.

Its compact design ensures low chip-to-chip times with a productivity increase of 15 percent compared to automated horizontal lathes.

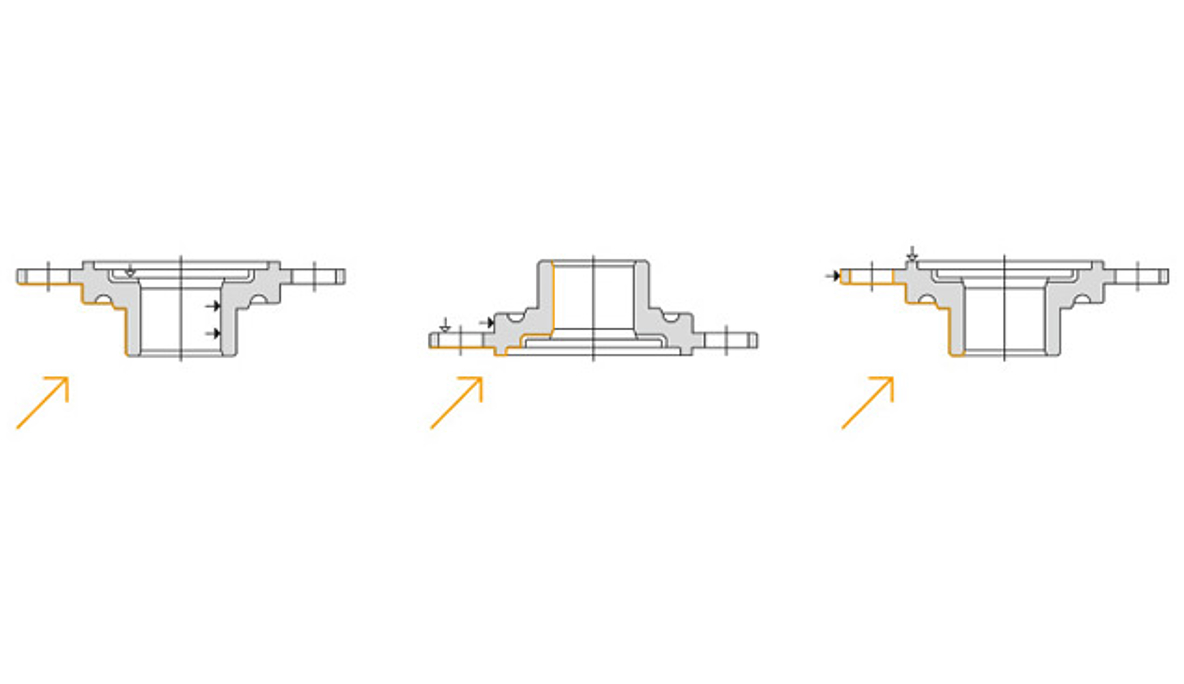

The flange is machined in three clamping operations via three VL 2 lathes, linked with L / U automation and flip-over units.

Complete machining in six clamping operations

| OP 30 | OP 20 | OP 10 |

|---|---|---|

| Smoothing, outer contour Smoothing, plane surface 35 sec. | Beveling and turning Face turning Turning, inner contour Turning, inner plane surface 34 sec. | Turning, plane surface Beveling and face turning Drilling Beveling, inside 34 sec. |

Production system for flanges with VL lathes

Complete machining of flanges in three clamping operations

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Machines for your requirements

(5) machines found

Automation Solutions