Horizontal Gear Hobbing Machines

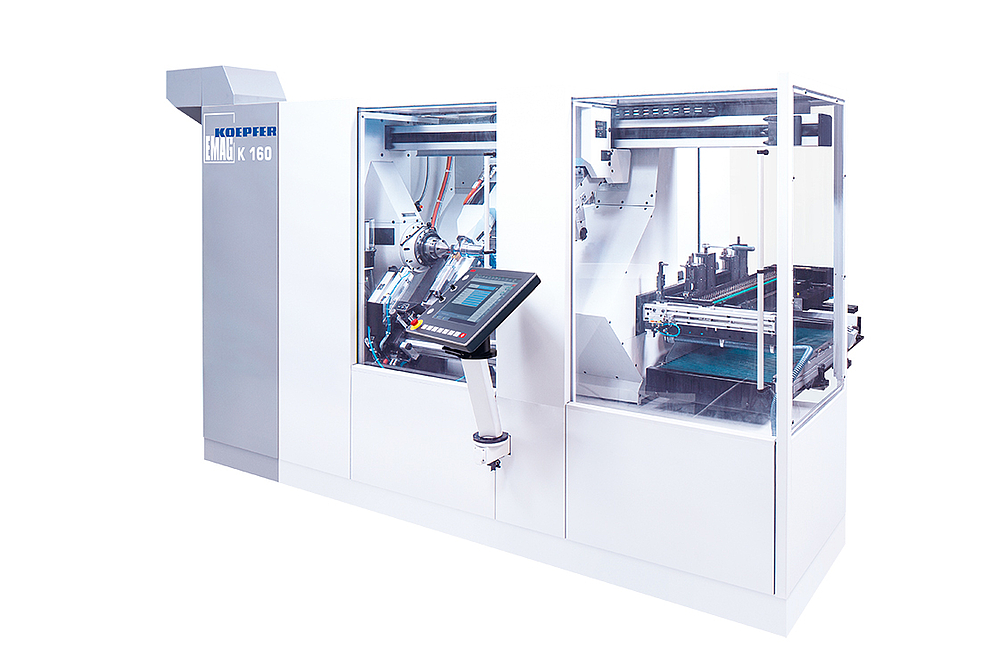

K 160

- Module range: mm 0.3 - 2.5

- Workpiece dia., max.: 100 mm | 4 in

- Workpiece length, max.: 1,000 mm | 39.5 in

Your Gear Hobbing Solution!

The K 160 gear hobbing machine combines an innovative design principle with state-of-the-art technology, and the wealth of experience gained during generations of gear cutting.

Whether used for dry or wet machining, customized automation equipment and an extensive technology package make the K 160 gear hobbing machine an optimal high-speed hobbing center for gear modules up to 2.5.

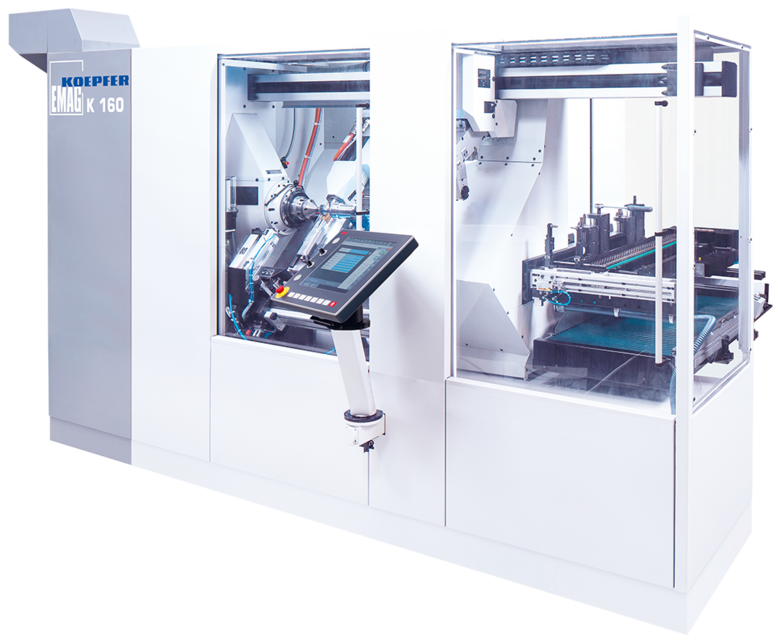

KOEPFER K 160 Horizontal Gear Hobbing Machine

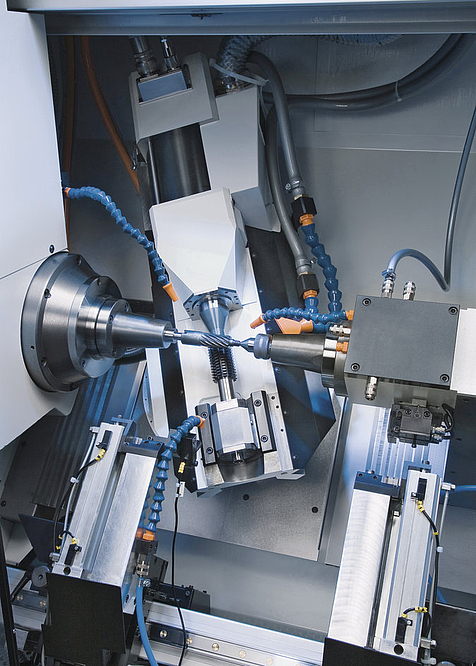

The K 160 gear hobbing machine is equipped with the latest generation of eight-axis control systems, and offers a high hobbing head and work spindle speeds. This makes it possible to use high cutting speeds, even on those pinions and shafts with the fewest number of teeth. The base of the gear hobbing machine is made out of MINERALIT® polymer concrete in a slant bed design.

This machine base, made of MINERALIT® polymer concrete, provides excellent vibration dampening properties and is torsion and bending resistant. The slant bed design is ideal for chip and coolant removal. These factors result in better surface quality and longer tool service lives.

Throughput and idle times are governed by cutting speeds, the workpiece loading process and ease of setting - all economically decisive factors in the machining of large batch sizes. For the machining of pinions and shafts with the smallest number of teeth, or just gear hobbing, the K 160 is the world's fastest gear hobber with the lowest chip-to-chip times. Eight to ten years ago, the machining times for armature shafts, for example, were approximately 20 to 25 seconds. The K 160 gear hobbing machine has, for the past several years, been the world's only machine to reduce them to 8 to 10 seconds.

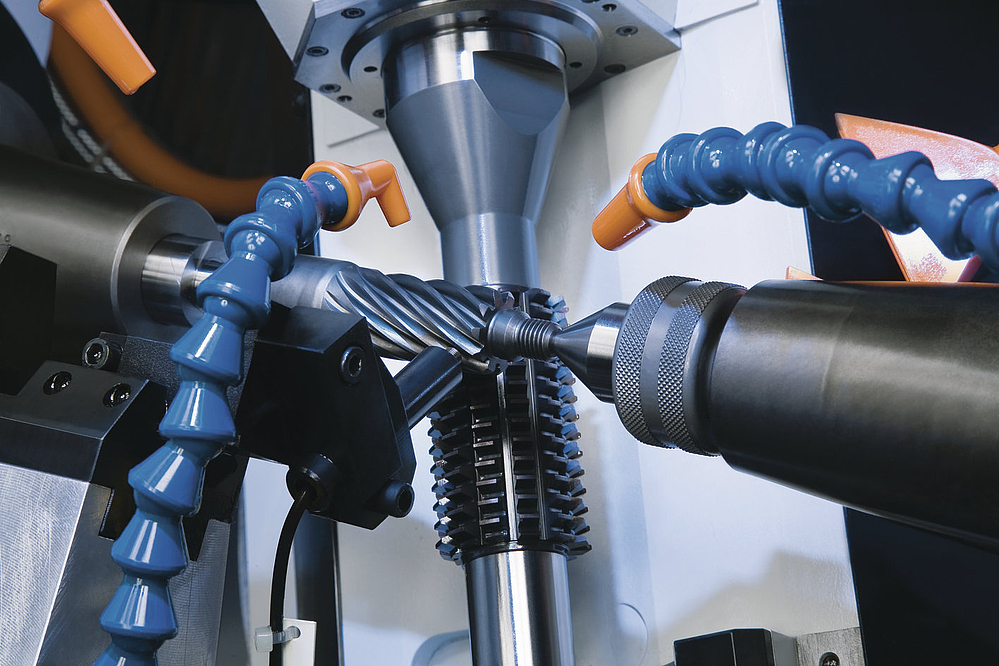

This position is due to the company's outstanding capabilities, not only in the high-speed dry hobbing of planetary gears and the high-speed gear cutting of armature shafts, but also in the tangential milling of worm gears.

Gear hobbing, how it should be.

Advantages K 160

- Workpiece fixture for wheel, pinion and shaft parts

- Hydraulic precision collet to clamp shank hobs

- Hydraulic quick clamping device for workpieces and hobs

- Deburring device (vibration dampener, carrier for rehobbing sensor) available in the single or double version

- Automatic chip removal unit

- Oil mist suction system

- Suction system for dry hobbing

- Automatic orientation for skiving

- Software for special programs such as skip shifting of a damaged area on the hob, for positioning tasks etc.

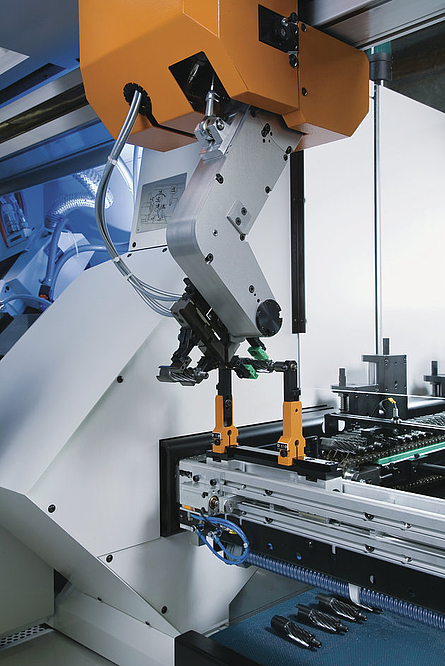

- Magazine loading-systems for blanks or semi finished parts

- Excellent vibration damping, resulting in extended tool life and superb surface finishes

- MINERALIT® polymer concrete is thermally stable which ensures constant production results

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Industry 4.0

Technical Data

Module range

0.3 - 2.5 mm

Workpiece dia., max.

100 mm

4 in

Workpiece length, max.

1,000 mm

39.5 in

| Module range | mm | 0.3 - 2.5 |

| Workpiece dia., max. |

mm

in |

100

4 |

| Workpiece length, max. |

mm

in |

1,000

39.5 |

| Hobbing length, max. |

mm

in |

200

/ 480

8 / 19 |