다이 생산을 위한 전해 가공(ECM)

다이와 같이복잡한 고강도 소재의 3D 구조를 가진 공작물을 결합하는 작업에는 매우 까다로운 가공 기술이 필요합니다.

다이 설계 시 설계의 자율성

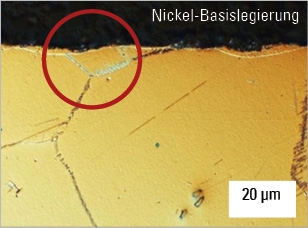

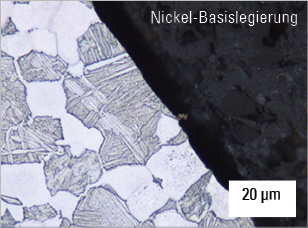

최대 4개의 축이 장착된 부품을 열의 영향 없이 전기 화학적 원리를 이용하여 PT 시리즈의 장비에서 가공합니다. 가장 까다로운 3D 구조도 전혀 문제 없습니다. 전기 화학적으로 이루어지는 황삭 가공 분야에서 전해 가공(ECM)은 이송 속도가 1분당 최대 5mm까지 도달합니다. 20~30개에 달하는 부품의 면삭 가공 또는 병렬 가공을 통해 대량/ 중량 생산 시에도 높은 생산성을 보장합니다. 생산 정확도는 최대 20마이크로미터 미만입니다. 게다가 전해 가공용 공구의 수명은 매우 깁니다. 따라서 절삭 공정과 비교하여 상당한 생산 비용을 절감할 수 있습니다. 이 외에도 부품의 안정성에 부정적인 영향을 미치는 방전가공 시와 같이 미크로 균열이 발생하지 않습니다. 이는 고성능 압입 공구에 있어 아주 중요한 요소입니다.

방전가공(EDM) 대 전해 가공(ECM)

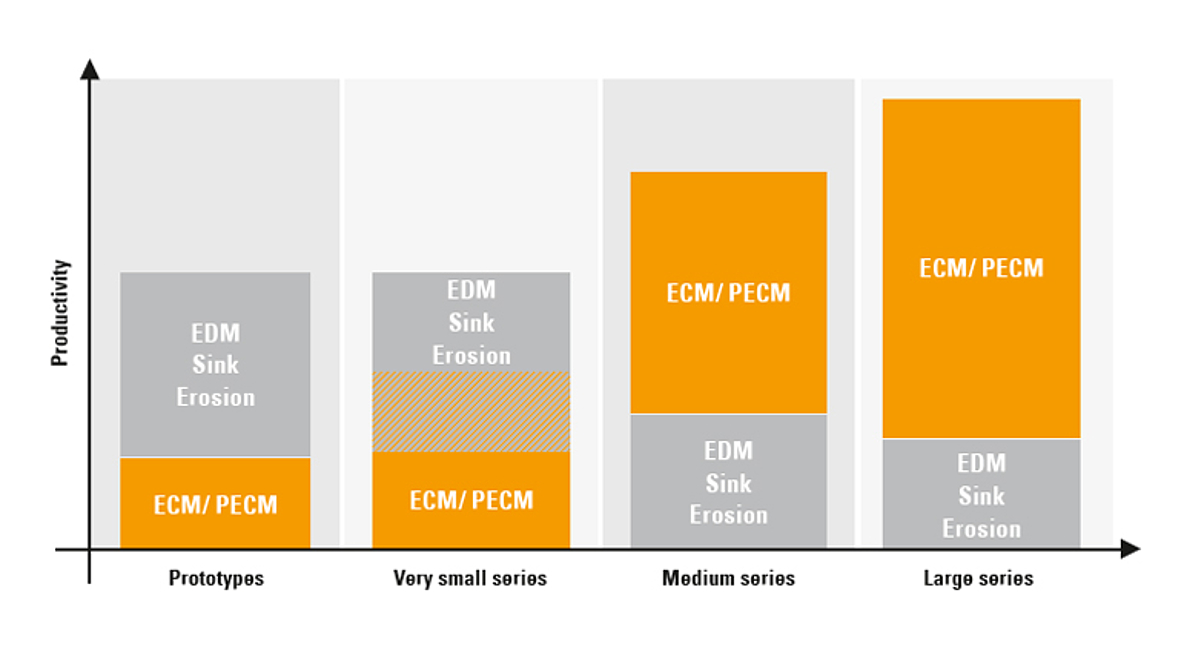

- 시제품 생산 시 EDM의 한정된 설비 요건과 전극 및 장치 면에서의 낮은 복잡성으로 인해 득점을 올립니다.

- 유닛의 개수가 증가하면서 ECM 공정은 장비의 무보수 공구 원칙과 그로 인한 장비의 긴 수명에서 큰 이익을 얻습니다.

EDM vs. ECM productivity comparison: Electro-chemical machining scores points in particular with high unit numbers because ECM operates without tool wear

기계 고객의 요구에 부응

(2) 대 기계 발견

언제든 도와드릴 준비가 되어 있습니다.

이 기계에 대한 문의 사항이 있거나 상세 자료가 필요하십니까?

연락처