利用埃马克的专业知识技术加工滚轧环

滚轧环属于精密部件,它对线缆的生产质量有着很大的影响。埃马克公司成功研发出一种工艺,能在极短时间内加工出高品质的滚轧环。

在大多数情况下,滚轧环只能在传统磨床上进行小批量手工生产。由于对滚轧环的精确度要求非常高,因此它的加工过程也格外复杂。滚轧环主要采用硬金属制成。为了获得所需的精度和表面质量,通常需要进行一道磨削加工。因此,每一个滚轧环的完整加工时间往往超过数小时。埃马克公司的研发人员致力于缩短这一繁杂工序的加工时间。如今,完整加工一个滚轧环只需要几分钟时间。最令人惊喜的是,还能保证达到卓越的加工品质。

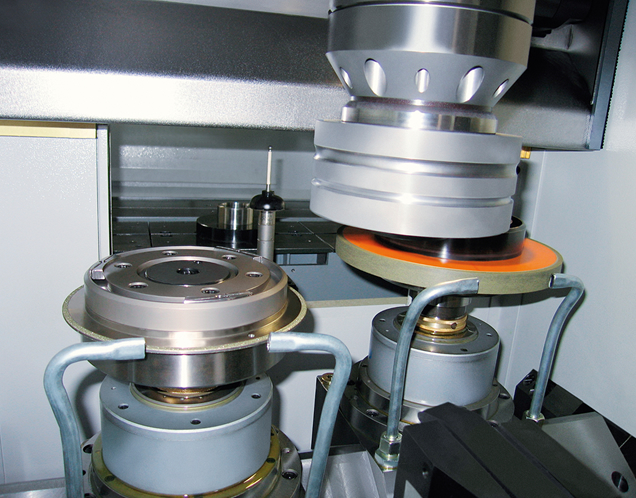

车磨中心 VSC DS 是滚轧环加工的理想选择

埃马克的研发人员选择VSC DS系列机床来进行加工。只要所使用的硬金属类型许可,在车磨中心上便可以组合使用车削和磨削这两种工艺技术。

由此可以大大提高加工质量和灵活性。但最主要的优势在于缩短了循环时间。在一台机床上完成全套硬精加工,可以大大缩短加工时间、运输时间和放置时间。此外,还可以减少安装步骤并缩短安装时间。

产量的提高主要依靠车削过程中的高进给量。与单一的磨床加工相比,可以大大提高粗加工的速度。

只有在对质量起决定性作用的精加工过程中才采用磨削技术。

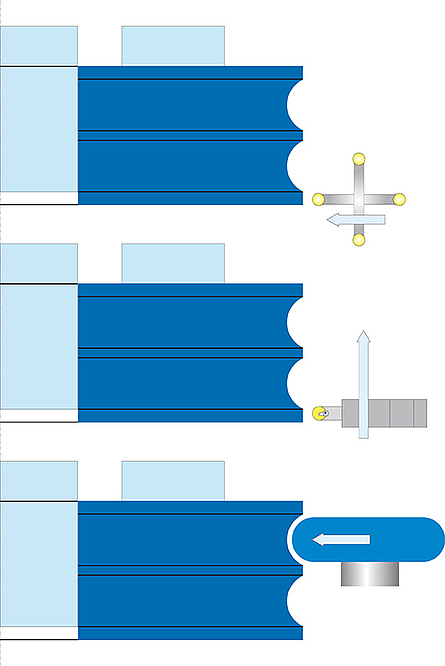

滚轧环通过工件输送系统被送入 VSC DS 车磨中心,并在测量工位上进行测量。然后根据测量结果进行硬车削工艺预加工。在进行滚轧环的精磨之前,还要再进行一次测量,以确保预加工工序达到所需的质量要求。整个加工过程可在一次装夹中完成,这样可完全避免装夹导致的错误,并在最短的加工时间内实现最高的品质。自动化生产还可以保证连续不断的生产过程,操作人员完全无需介入。

机床 满足您的要求

(1) 款机床已找到

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/_processed_/8/e/csm_vl-2_preview_00384ae706.png)