采用高精度热套技术制造凸轮轴

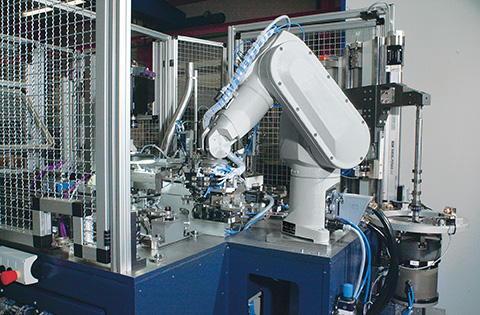

凸轮轴的精密制造对生产提出了苛刻的要求。埃马克的热套技术灵活性高、生产效率高:设计灵活、生产节拍时间短。

热套装配技术完美适用于凸轮轴装配制造

装配式凸轮轴的市场占有率持续增长,其主要原因是它一体式结构,大大减轻了零件的重量。装配式凸轮轴目前也进军卡车行业。

凸轮轴的优势众所周知:低成本、轻重量、可选择不同的材料制造零件、生产灵活性高、可轻松实现任何新的几何形状,如负凸轮半径。鉴于需要降低燃料消耗和二氧化碳排放量,市场对凸轮轴的需求不断增加。

EMAG 热套装配= 精密连接

埃马克热套装配技术,是一种无反作用力的连接技术,因此凸轮可以高精密的连接到管子上。最重要的是控制温度和时间,以及连接设备的机械设计的专业知识。

通过机械手和特殊设计的装夹技术,可在小于15 µm 的间隙中运行自如。该设计概念非常灵活,在凸轮轴的设计上有很大的自由度,非常适合产品型号频繁变化的中等批量生产。采用这种方式连接的凸轮轴精度高,可大大降低凸轮外侧的磨削,或者甚至在使用精密凸轮时完全消除。该方法的另一个优点是可以在一个轴中使用不同的材料。除了用100 Cr 6等材料制成的锻造凸轮外,还可选择包括精磨凸轮或尺寸精确的烧结凸轮,这些凸轮不需要后续的精磨。诸如插头和端件之类的辅助部件可以由较便宜或较轻的材料制成,就像实际的轴本身一样。 所有这些都使得凸轮轴能够适应发动机的要求,并在承载能力和制造成本方面进行优化。

优势 装配式凸轮轴(热套)

热套装配优势:

- 高精度,热套之后无需精加工

- 节约材料、降低重量

- 热套后无变形

- 可不同材料组合

- 可自由选择组件序列

- 可自由选择角度和轴向位置

- 如产品发生变化,可快速重置

装配式凸轮轴优势:

- 低成本

- 重量轻

- 凸轮可由不同材料制成

- 生产灵活性高

- 可轻松创建新凸轮形状,如负半径

机床 满足您的要求

(1) 款机床已找到

工艺

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/joining-machines/sfc-600/sfc-600_preview.png)

我们竭诚为您服务。

您有任何问题或需要有关该机床的详细资料吗?

联系我们