硬车 / 磨削

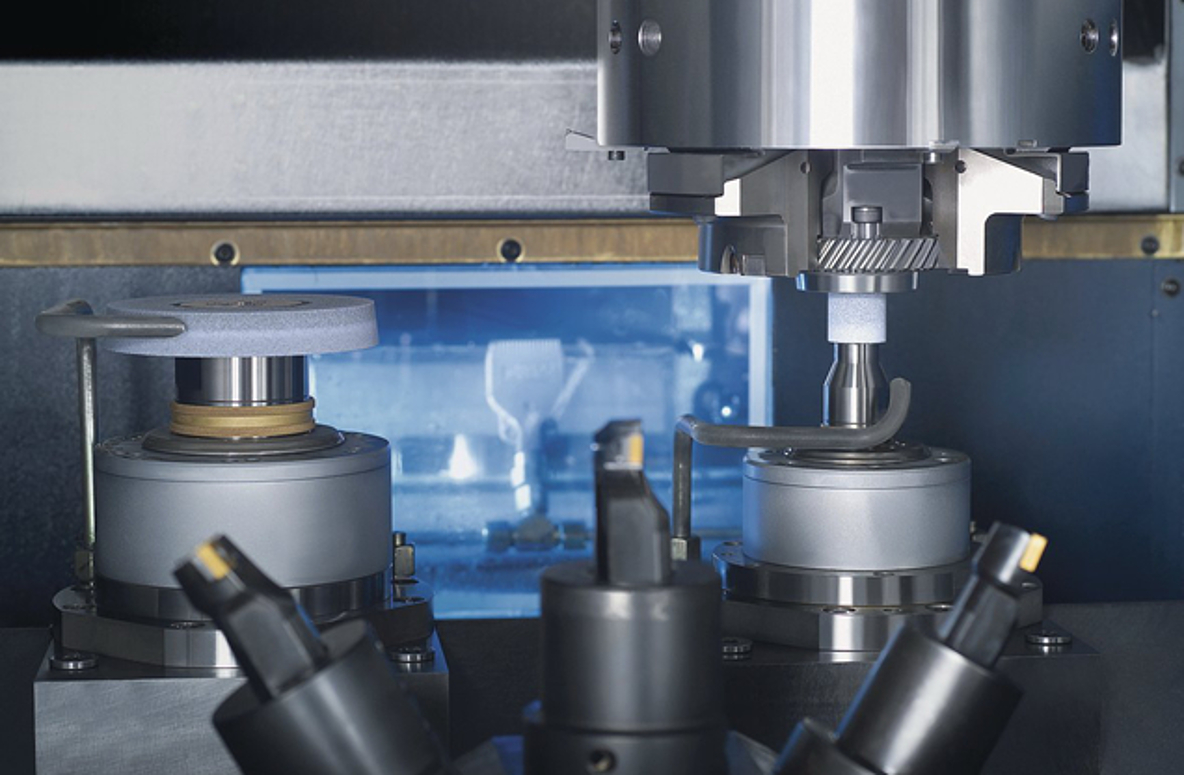

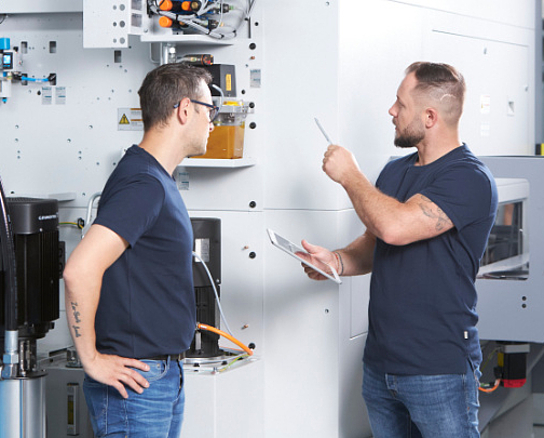

许多工艺组合,例如在一台机床上实现硬车/磨削,可以开发出相当大的合理化潜力。

硬车/磨削工艺结合的优点在于工件的整体加工,具有较大的灵活性,以及提高生产效率。

硬车/磨削:提高质量和高灵活性

使用组合工艺(硬车/磨削)效果非常好,可减少节拍时间。如果在一台机床上完成精加工(硬车/磨削),可大大减少运输和存储时间。在工作量和设置时间上也大有优势。

硬车和磨削技术已在某些领域得到应用并彰显其优势

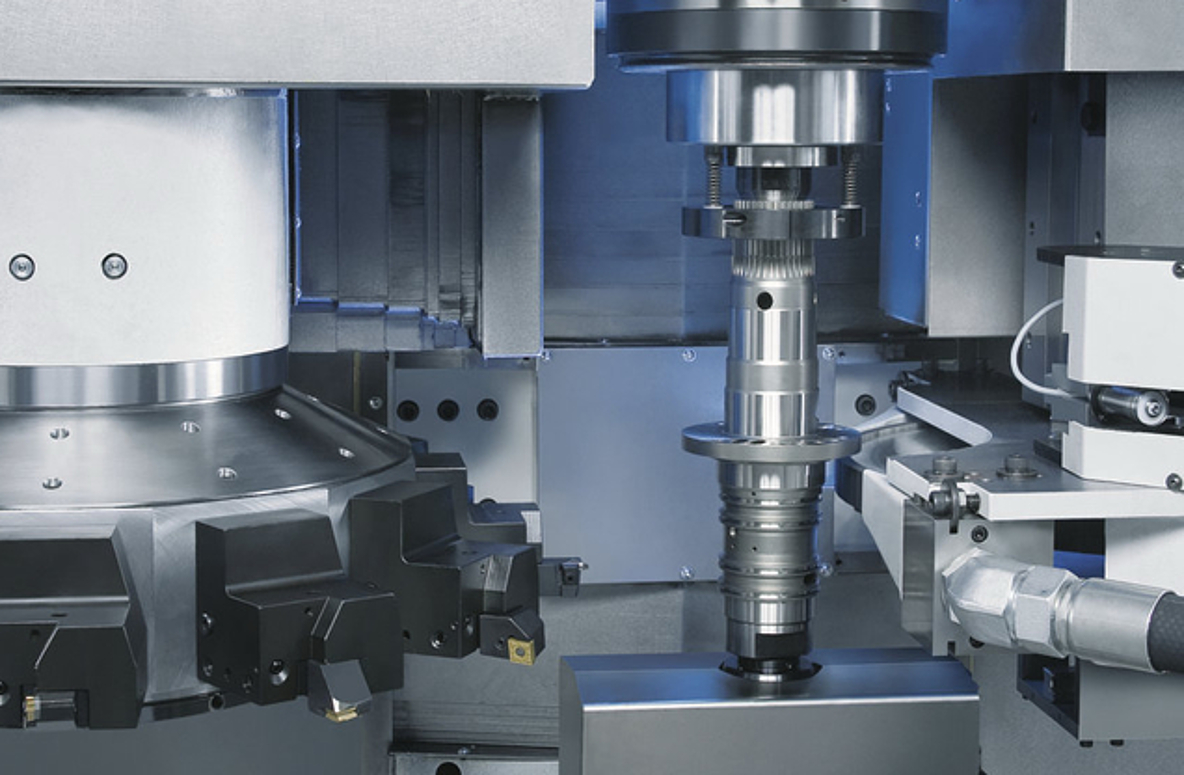

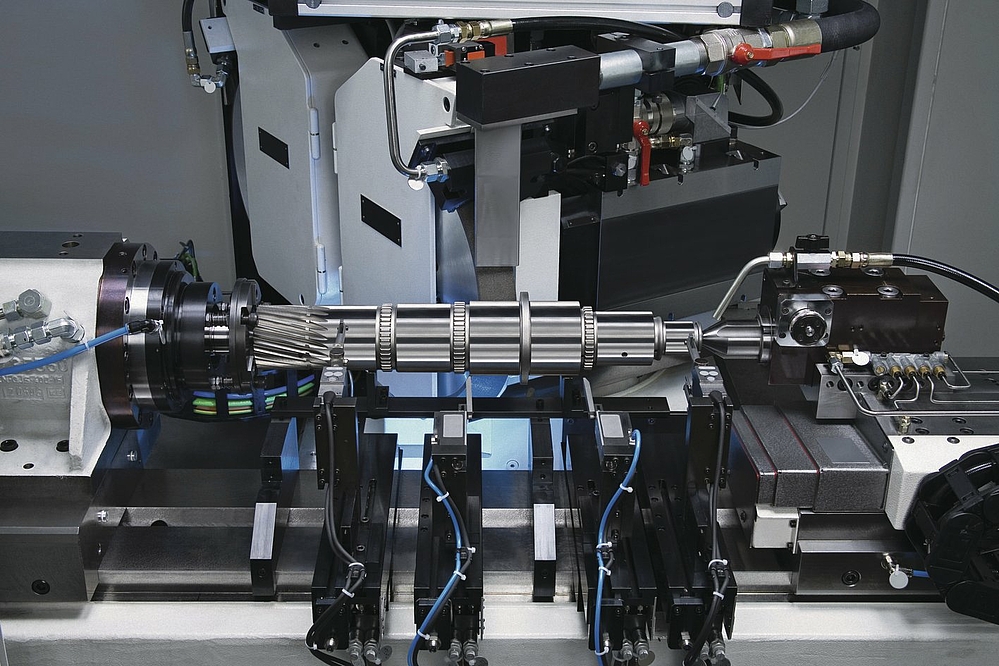

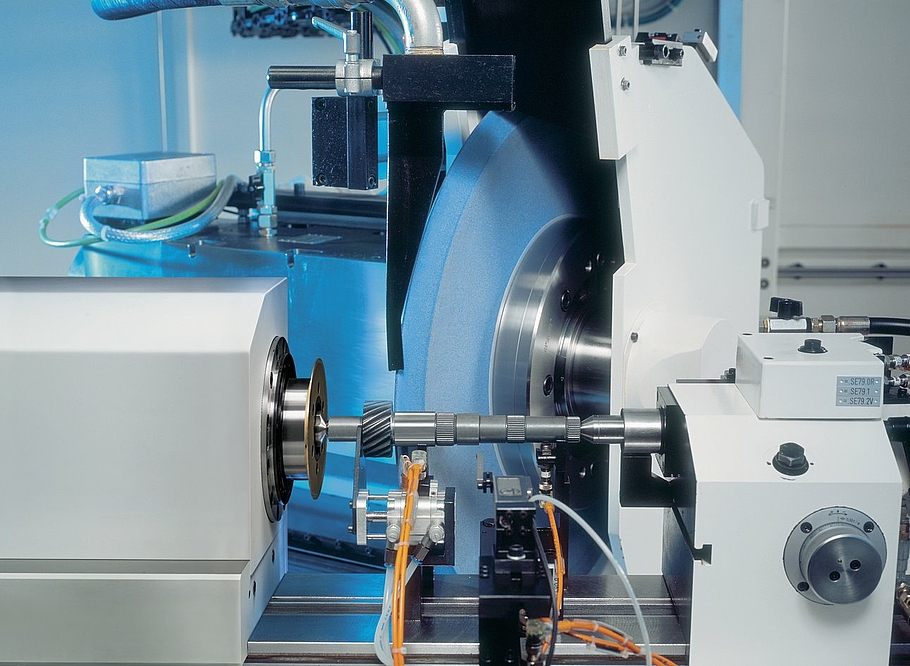

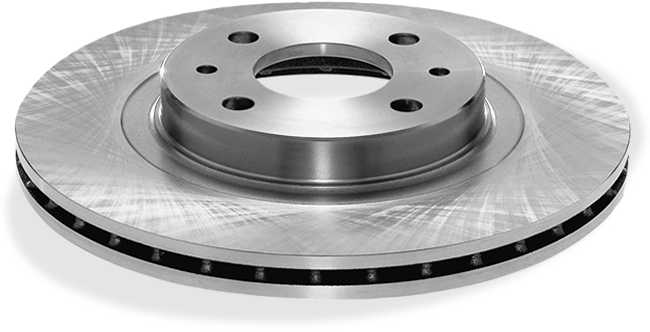

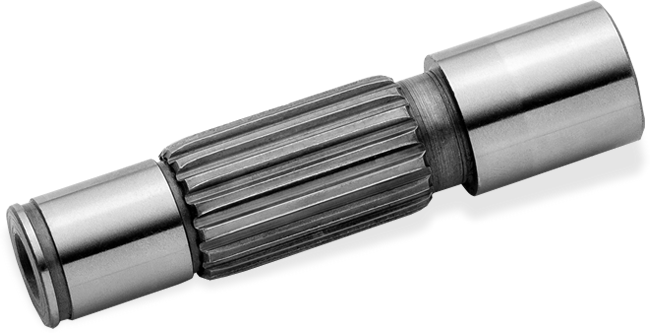

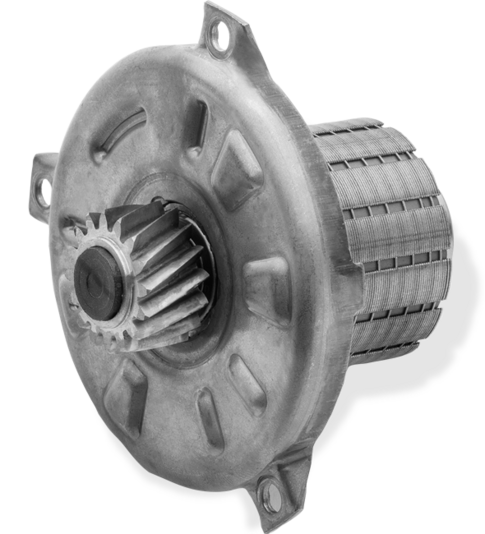

在加工盘类件时(VSC DS 硬车/磨削机床),硬车/磨削组合工艺是目前先进的技术。然而,仍然有相当大的合理化潜力有待发掘, 因为并非所有可使用硬车/磨削组合工艺的工艺都已改变。未来,除了硬车/磨削外,将会有更多的工艺组合,如硬铣削、硬铰孔和研磨等。对于轴的加工,市场也提供了合适的机床概念,集成了硬车削/磨削工艺(VTC 315 DS 轴类件硬车/磨削机床)。然而,这些系统并不像盘类件的硬车/磨削组合工艺那样普遍,因为已经有基于传统磨削工艺、CBN技术和现代车削系统的高效系统存在。 但有迹象表明,硬车/磨削组合工艺带来的优势将会更频繁的用于轴类件的加工。

总之,硬车/磨削组合工艺不再是一件奇特的事,技术和机床都经过了测试。使用硬车/磨削组合工艺以及其他生产工艺的集成,都将有助于进一步开发合理化的生产潜力。

硬车 / 磨削-加工工艺比较

传统的外圆切入磨削技术

传统外圆切入磨削技术仍为许多公司广泛应用。虽然这一技术应用时间已很长,大家对这一技术的经验也必较丰富,但涉及到创新时,该技术有很多美中不足之处, 原因是这一技术在长期的使用过程中已不断被优化,现在几乎已不再有优化空间。

硬车

在许多应用中,硬车技术和传统的磨削技术往往会势均力敌,形成某种竞争局势。硬车的特点无容质疑也是柔性高,另外是可以干加工。但硬车的不足之处是工艺稳定性问题。由于存在不可预见的断刀问题,所以硬车的工艺不稳定。另外标准机床硬车时可达到的工件质量局限在IT6范围内。

CBN磨削

和传统磨削技术相比,采用CBN切入磨削的一大优点是能够大幅度减少主加工时间。除此之外,由于CBN砂轮的寿命长,所以也在一定程度上减少了非机加工时间。CBN磨削技术的缺点是:由于刀具的绝对价格高,所以只适合于系列或批量生产。

高速外圆成型磨削或无纹路磨削技术则是对CBN磨削技术的有效补充。高速外圆成型磨削或无纹路磨削一般采用窄砂轮,加工时砂轮数控走过轮廓轨迹,从而生成工件形状。这一技术的优点是柔性高,特别适合用于同一家族工件的加工。 其缺点则是因采用高速磨削技术,并需要采用磨削油,所以机床的投资费用稍高.

硬车 / 磨削组合工艺应用

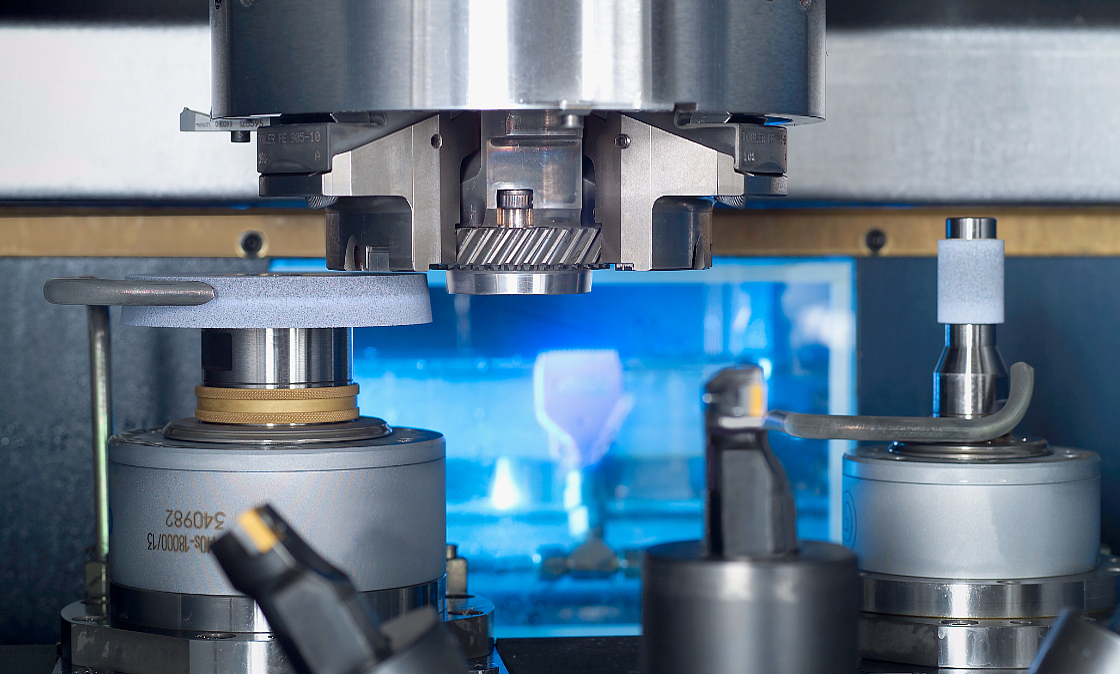

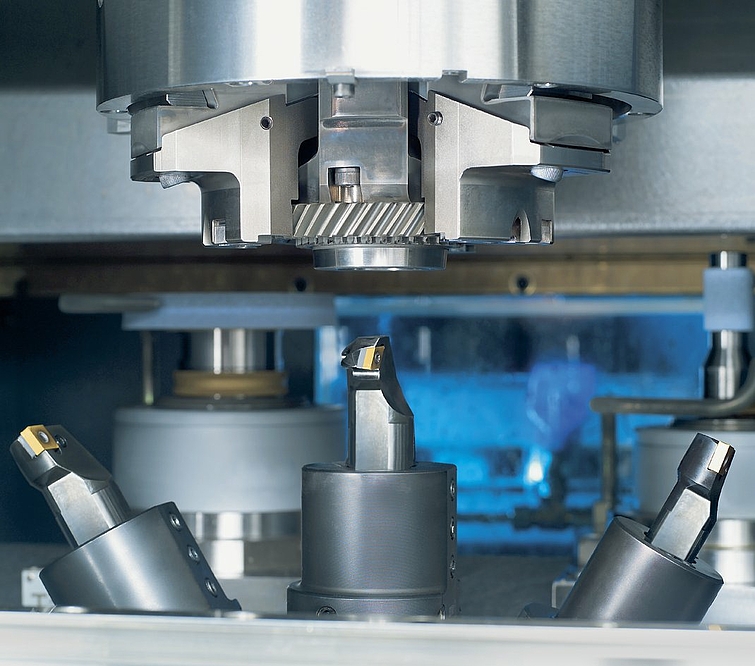

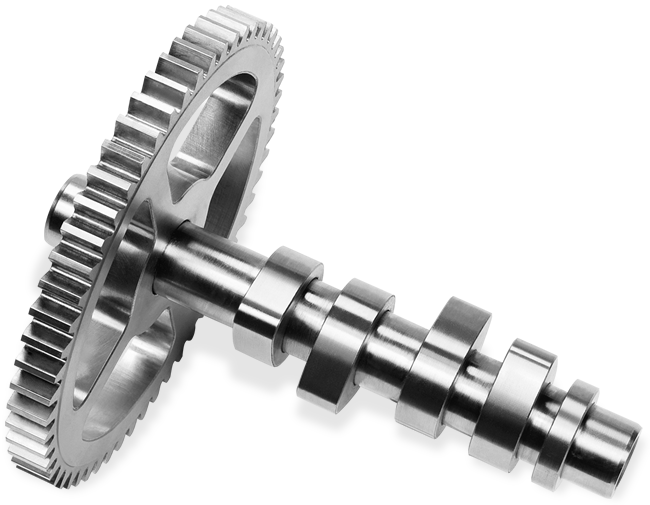

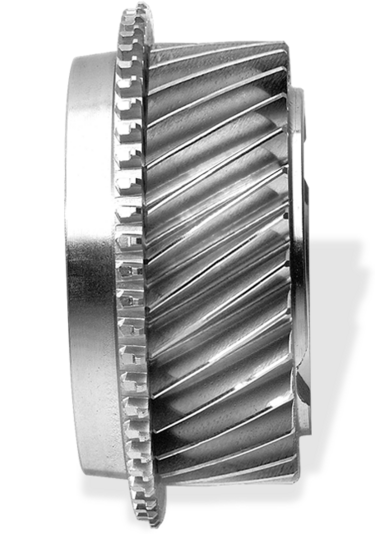

硬车/磨削组合工艺加工的典型案例是齿轮加工。齿肩完成硬车。由于孔和锥的质量要求高,所以需要预车和精磨。为此,机床安装了两根磨削主轴,一个用于镗孔加工,一个用于零件外截面加工。由于只需研磨掉百分几毫米,所以必须研磨刀具必须是用于精加工。同时,这种组合工艺在很大程度上取代了单工艺磨床,并且是公认的先进工艺。

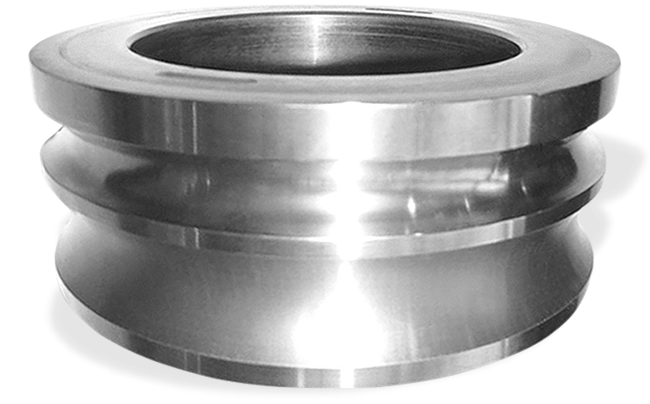

另一个硬车/磨削组合工艺的应用实例是无螺纹座椅的加工。压力环的外径和表面需要加工,因此 O/Ds 表面必须是无螺纹。因此,表面硬精车, O/D 预车和精磨即可完成。通过将砂轮插入平行轴定位成型棍进行修整。磨削工艺也是切入式,这样可确保磨削后无螺纹产生。

另一个有趣的组合工艺加工示例是内部带有滚珠轨道的螺母,如滚珠丝杠上所用。这些螺母需要加工内螺纹、螺母表面、O/D和肩部。首先对螺母表面、O/D和肩部硬车,所有球轨道上的内螺纹进行磨削。像VSC 机床,配备Y轴和B轴,是非常理想的。高精度B轴允许设置螺纹的导角,而Y轴用作加工滚柱轨道的进给轴。机床配有2根磨削主轴,用于预车和精加工,也可配备各种刀具。所述的磨削工具采用单独的修正附件修整,配备金刚石修整轮。该机床适用于普通砂轮和金刚石砂轮的修整。2.5D测量头用于确定工件的精确角度位置,也可用于硬车削表面的后处理控制。

与传统的顺序工艺相比,这一设计的优势在于所有质量定义表面都可在一次设置中完成,因此避免了重新装夹误差,特别是影响螺纹面与O/D和球槽中心线的对准。

Finishing a gearwheel with hard turning and grinding operations on an EMAG VSC 250 DDS.

Combination machining hard turning and grinding of shafts. All precision-machining processes on a single machine: CBN grinding, hard turning and scroll-free turning, providing exceptional flexibility in the precision-machining of shafts.

机床 满足您的要求

(6) 款机床已找到

工件

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/turning-machines/customized-vlc/vlc-100/vlc-100_preview.png)

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/turning-machines/customized-vlc/vlc-200-gt/vlc-200-gt_preview.png)

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/turning-machines/customized-vlc/vlc-350-gt/vlc-350-gt_preview.png)

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/grinding-machines/grinding-machines-shafts-vtc/vtc-100-gt/vtc-100-gt_preview.png)

![[Translate to Chinese (2):] [Translate to Chinese (2):]](https://cdn.emag.com/fileadmin/user_upload/content/machines/grinding-machines/grinding-machines-shafts-vtc/vtc-315-ds/vtc-315-ds_preview.png)

我们竭诚为您服务。

您有任何问题或需要有关该机床的详细资料吗?

联系我们