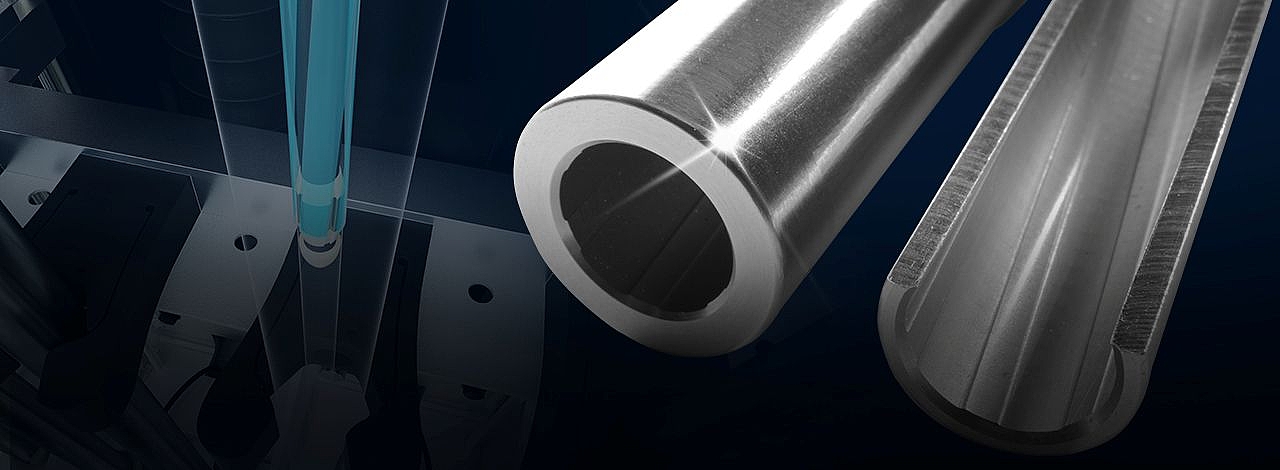

ECM Rifling: Reduce your manufacturing costs while increasing precision

In our recorded webinar, we will introduce you to electrochemical machining (ECM) for rifled barrels. This innovative process offers key advantages:

- Material-friendly machining: No mechanical or thermal stress on workpieces

- Longer service life: Manufactured barrels achieve longer service lives thanks to gentle machining

- Lower capital investments: Cost-efficient alternative to conventional manufacturing processes

- Maximum flexibility: Enables a wide variety of twist geometries without tool changes

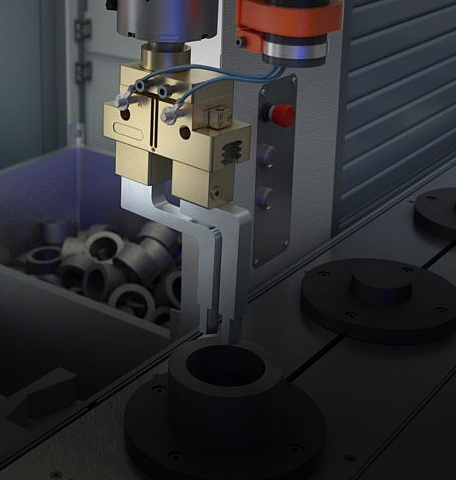

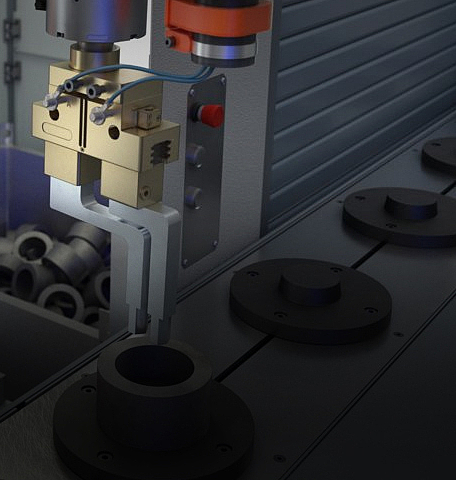

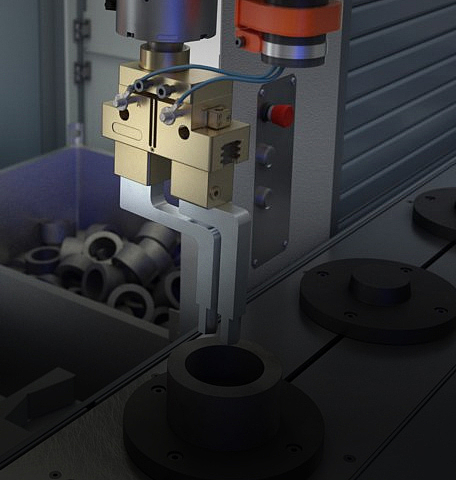

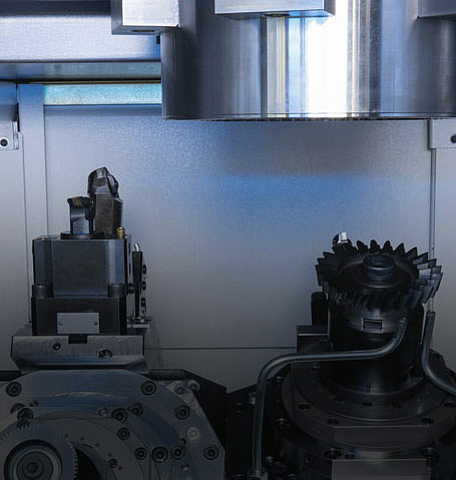

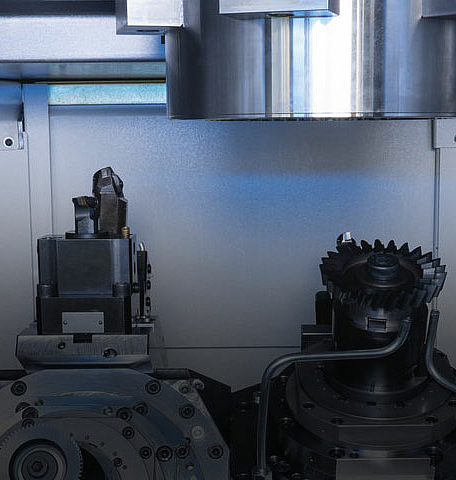

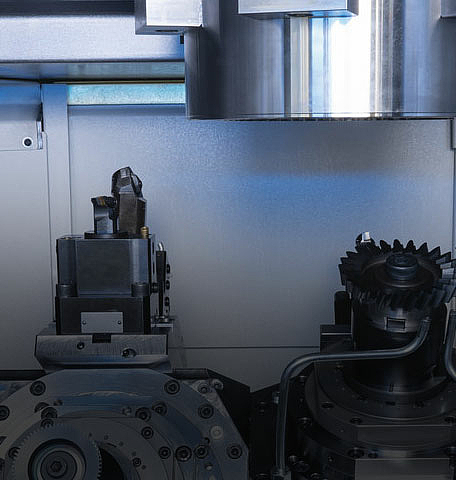

Increase your production capacity

Find out how modular system configurations can sustainably increase your productivity. From the simultaneous machining of multiple barrels to parallel machining for large series – we’ll present proven solutions for a range of production requirements.

What you’ll learn:

- How ECM avoids mechanical and thermal stress for longer barrel life

- Cost advantages compared to traditional machining methods

- How to achieve complex twist geometries without tool changes

- Modular ECM configurations for scalable production

- Real-world quality gains and precision improvements

- Implementation of polygonal, progressive and conventional rifling

Videos & Downloads

Das könnte Sie auch interessieren ...

Registrierung Mediathek