Articulated Cages are processed on VTC 100-4 Vertical Turning Centers

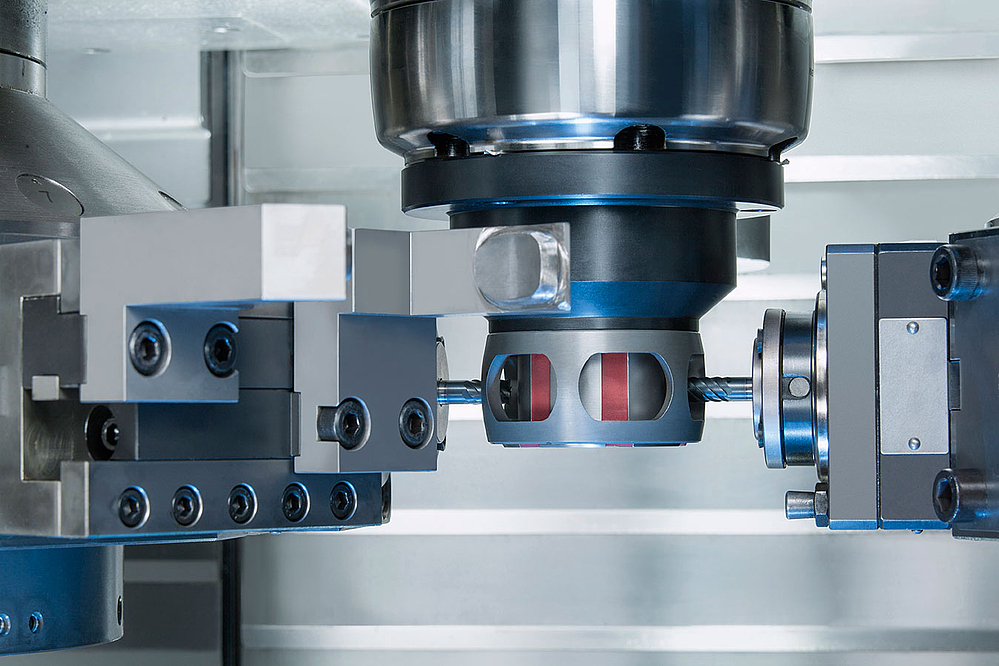

Articulated cages are completed automatically on the 4-axis turning centers of the VTC series. The external turning and the window-milling of articulated cages are done in one clamping operation. The VTC 100-4 vertical turning centers load themselves independently due to integrated automation. This ensures highly efficient production.

4-axis Machining of Articulated Cages

Articulated cages are produced in high volumes which is perfect for the VTC 100-4 4-axis turning center. Loading and unloading of the machine is done by the turrets. While one workpiece gripper (in the turret) moves a raw part into the machine, the other gripper simultaneously picks up the finished articulated cage. The entire process only takes a few seconds.

Technologies for machining of articulated cages:

- External turning

- Milling of windows

- Soft and hard machining

Advantages Articulated cage

Advantages of the VTC 100-4 for machining articulated cages

- Simultaneous production of two cage windows due to 4-axis machining

- Minimal non-productive time due to simultaneous loading and unloading of articulated cages

- Integrated automation system and part-storage unit

- Easily accessible machining area and service units

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Machines for your requirements

(1) machines found