Archive

(53) News found

04/03/2023 - Oliver Hagenlocher - Press

Markus Clement becomes new CEO of EMAG GmbH & Co. KGDr. Heinz-Jürgen Prokop will hand over the CEO position to Markus Clement on April 1, 2023. "My mandate was to lead EMAG until a long-term and forward-looking appointment is found for this responsible position. Markus Clement and I made contact very…

02/15/2023 - Oliver Hagenlocher - Press

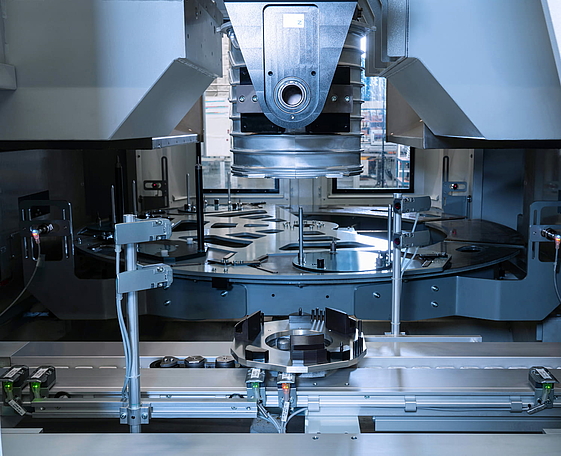

TrackMotion, Robots and Co.: How Suppliers and Contract Manufactures Benefit from Lean Automation SolutionsThere are many reasons for using automation and robotics in the manufacturing industry, ranging from compensating for a lack of manpower and simplifying production processes to reducing unit production costs. The latest generation of solutions makes…

01/16/2023 - Oliver Hagenlocher - Press

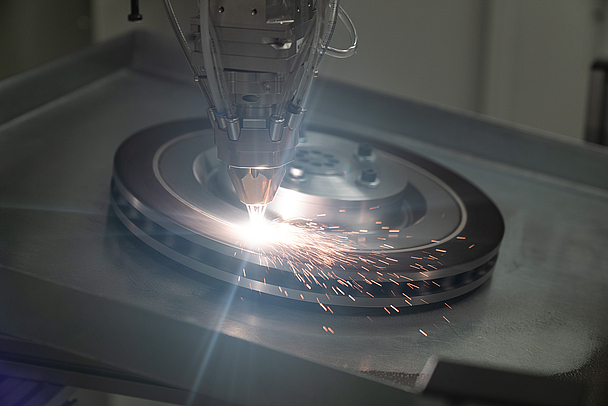

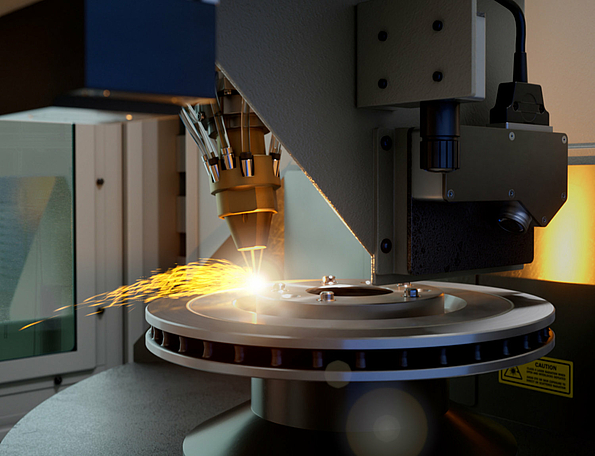

The EMAG Group and HPL Technologies conclude extensive Cooperation AgreementEMAG and HPL Technologies agree on an extensive cooperation in the field of hard coating of brake discs. Hard-coated brake discs are the preferred solution for compliance with the "EURO 7" fine particulate matter limits.

11/07/2022 - Oliver Hagenlocher - Press

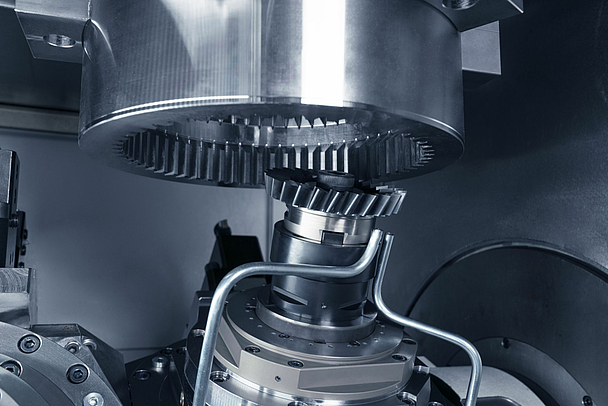

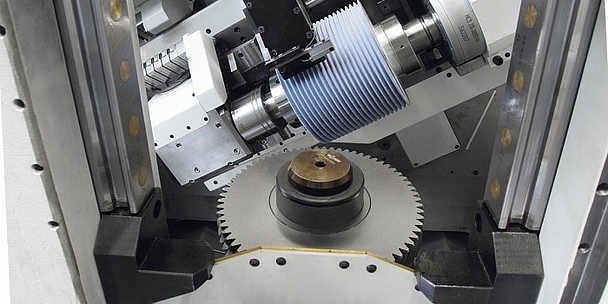

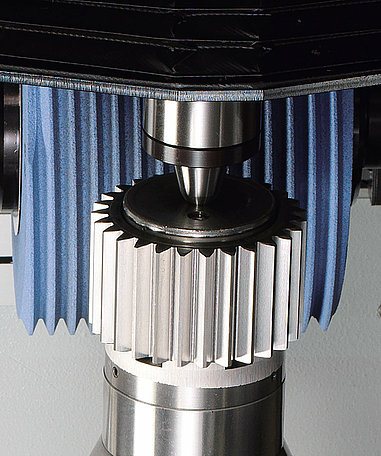

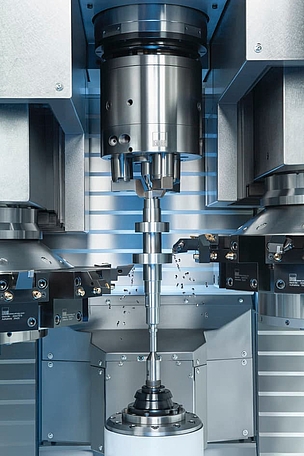

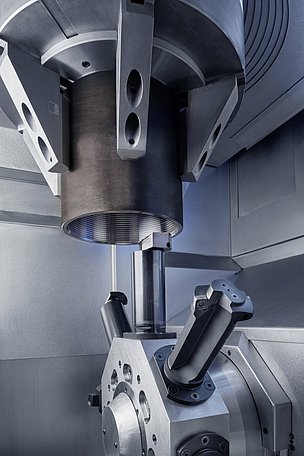

VSC 400 PS is a Marvel of Efficiency: Combining Power Skiving and Turning – For Complex Gear Cutting SolutionsFor many gear manufacturers, power skiving is getting very interesting, and not without reason, since the technique is much faster than shaping and more flexible than hobbing and broaching. However, for many years, the technique was considered quite…

09/26/2022 - Oliver Hagenlocher - Press

New management trio at EMAG making plans for the futureA new company management trio combined with a whole range of new products and innovations – EMAG is moving into the next few months with real momentum, and can look back on a successful first half of the year with a very strong order intake. There…

08/30/2022 - Oliver Hagenlocher - Press

EMAG at the AMB 2022 in Stuttgart: Making industrial production more flexible, more productive, and more sustainableMaximum productivity and sustainability, with flexible machine solutions for many different production tasks and sectors – this best summarizes the EMAG Group’s focus for this year’s presence at the AMB from September 13 to 17 in Stuttgart. At the…

07/26/2022 - Oliver Hagenlocher - Press

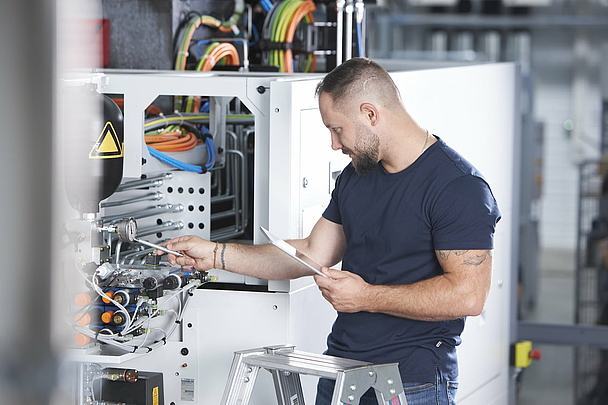

Inspection and Maintenance by EMAG: Reduce unnecessarily costly machine downtimes through targeted measuresThe greatest benefit of regular maintenance in industrial production is obvious – unscheduled machine downtimes are systematically avoided, which has a huge economic benefit for users. Take, for example, a turret. Investing a little money in having…

06/20/2022 - Oliver Hagenlocher - Press

Laser Applications for ElectromobilityThere are various challenges in the field of electromobility or, to be exact, in industrial production for electromobility. The drive train must meet very high requirements in terms of precision, weight optimization, new environmental standards, etc.…

04/21/2022 - Oliver Hagenlocher - Press

EMAG at the Grinding Hub 2022Grinding solutions for components from electromobility, data-optimized production and much more

01/20/2022 - Oliver Hagenlocher - Press

Laser cleaning by EMAG LaserTec: effective cleaning processes in a very small spaceMany workpieces need to be “clean” for the next production process to start. The choice of cleaning method plays a crucial role here. It must be configured in such a way that just the right amount of energy and time is used to satisfactorily remove…

01/03/2022 - Oliver Hagenlocher - Press

EMAG sells EMAG eldec GmbH as part of a management buy-out (MBO)EMAG eldec GmbH becomes eldec Induction GmbH. All jobs will be retained. The previous managing director Thomas Rank takes over the shares of eldec GmbH from the EMAG Group.

12/14/2021 - Oliver Hagenlocher - Press

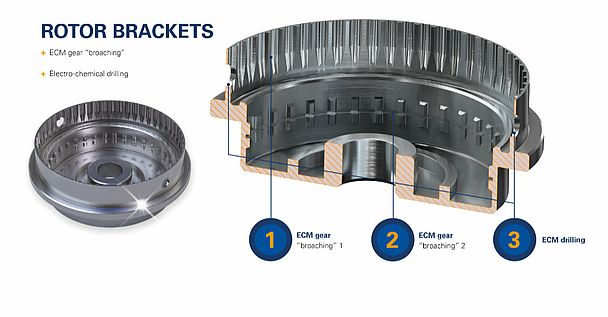

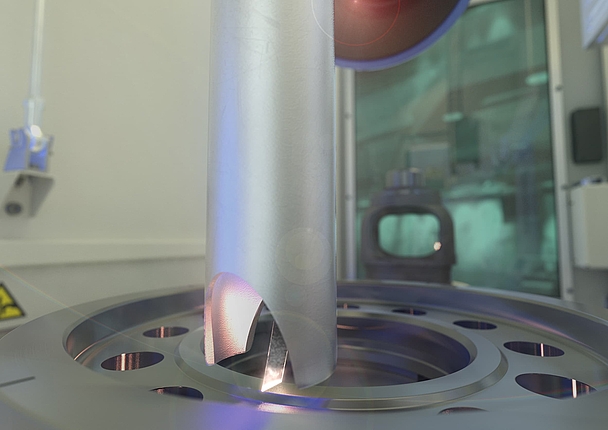

Electrochemical Machining from EMAG ECM: Electricity instead of drills and milling cutters: ECM as an alternative to metal cuttingElectrochemical metal machining (ECM) is an established technique for burr removal. However, ECM can do much more. The EMAG ECM Company wants to use the process to replace conventional drilling, broaching and even milling. A number of advantages over…

11/04/2021 - Oliver Hagenlocher - Press

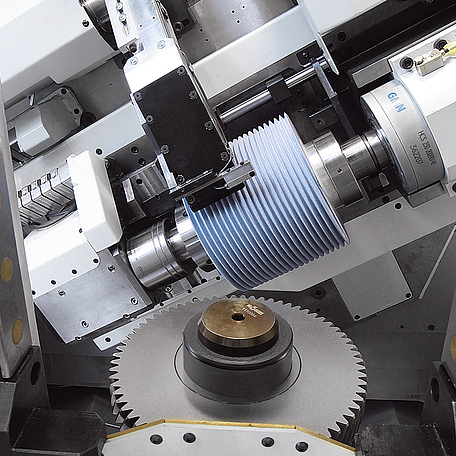

EMAG SU: High-tech solutions for top component quality when cutting gear teethSectors ranging from the automotive industry, aerospace technology, transmission engineering, and numerous others are going through a technological transformation, with many users requiring increasingly powerful production solutions to reduce their…

10/25/2021 - Oliver Hagenlocher - Press

Vertical Turning Center from EMAG Scherer: Machining Large Quantities of Stator Housings with Speed and PrecisionElectric cars still account for a relatively small proportion of total car sales, and a trend toward rapid growth for electric car production is still a long way off. But there are exceptions, as demonstrated using EMAG Scherer’s technology at a…

10/04/2021 - Oliver Hagenlocher - Press

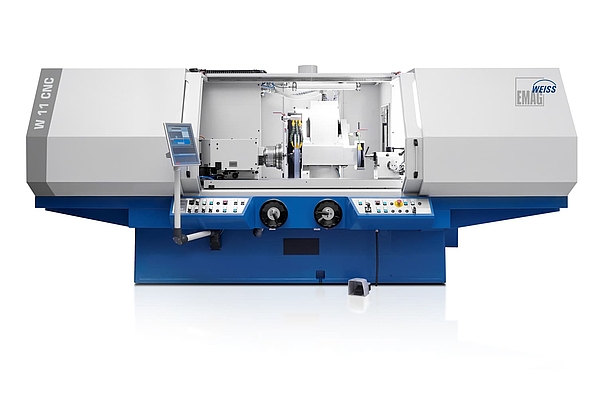

Universal cylindrical grinders from EMAG Weiss – the right solutions for virtually every user.The EMAG Group is breaking new ground with the universal cylindrical grinders from EMAG Weiss. The company from Salach, near Stuttgart, Germany, is mainly known for its (grinding) machines intended for high-volume production. But the machines from…

09/29/2021 - Oliver Hagenlocher - Press

Workshop and data analysis package: EMAG partner anacision speeding up the pace of Industry 4.0 implementationIndustry 4.0 is very much on the rise in Germany. According to a survey carried out last year by digital association Bitkom, roughly six in ten German companies are already relying on applications from this field. However, just 14% of them are using…

09/13/2021 - Oliver Hagenlocher - Press

EMO 2021 in Milan: EMAG shows highly flexible production solutions for electromobilityHighly flexible and at the same time productive grinding and turning processes for electromobility and co. - this is the claim EMAG is making at this year's EMO in Milan from October 4 to 9. Among other things, the focus will be on the G 250 machine…

09/06/2021 - Oliver Hagenlocher - Press

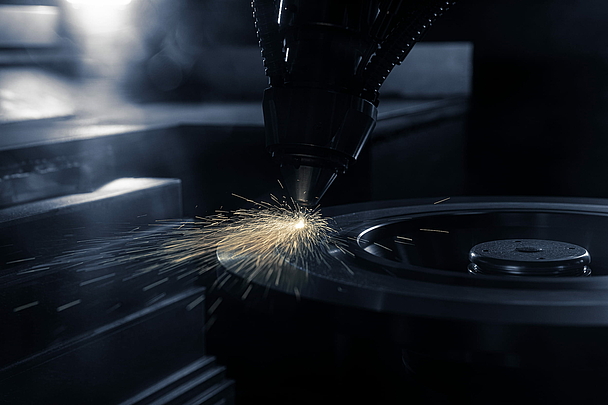

Laser Metal Deposition: EMAG develops production solution for coated brake disksThe car brake disk of the future is wear-resistant – and lasts as long as the car. This is made possible by a two-layer carbide coating that is applied to the disk using laser welding. EMAG LaserTec is currently engineering the associated integrated…

07/22/2021 - Oliver Hagenlocher - Press

Analysis of high-frequency data for anomaly detection: New method enables evaluation during operation – “in-process anomaly detection” in manufacturingAt many supplier companies, the production conditions are subject to constant change: On the one hand, automotive components are getting increasingly complex. On the other, the OEM requirements for dimensional accuracy and tolerances are growing…

06/02/2021 - Oliver Hagenlocher - Press

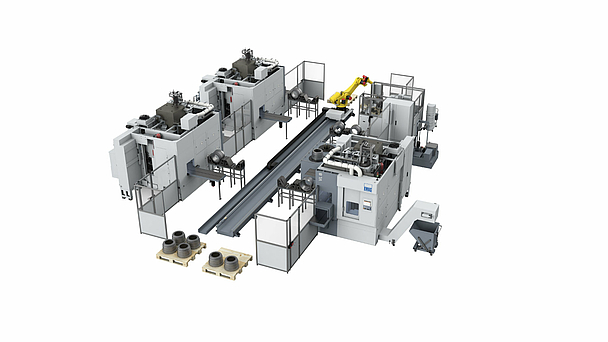

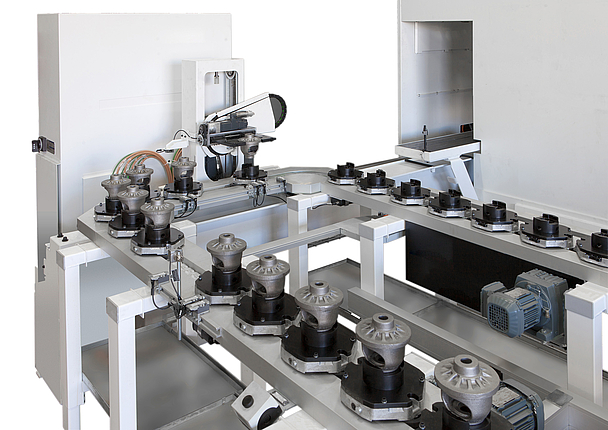

Manufacturing Solution for Trucks: EMAG presents a Compact Manufacturing Solution for Truck Wheel HubsThe race for future market shares is proof that e-mobility is not only shaking up the passenger car sector, but has long since taken hold of the truck sector as well. Established manufacturers are being joined in the market by a number of newcomers…

05/10/2021 - Oliver Hagenlocher - Press

Manufacturing solution for trucks: EMAG presents a compact manufacturing solution for large brake drums in the commercial vehicles segmentTrucks are the most commonly used means of freight transportation in the world. In Germany, more than 71 percent of goods are delivered by truck; in the USA, that figure is up to 72.5 percent. More than 3.2 bn tons of goods were moved on German roads…

03/16/2021 - Oliver Hagenlocher - Press

Vertical Turning Center for Shafts: 4-axis Machining of Rotor Shafts, Transmission Shafts and moreThe VTC 200 shaft turning center delivers top performance in high-volume series shaft production.

02/16/2021 - Oliver Hagenlocher - Press

EMAG Group Acquisition: Samputensili Machine Tools and Samputensili CLC have become EMAG SUThe acquisition of Samputensili Machine Tools and Samputensili CLC by the EMAG Group - including the 87 employees across two sites near Bologna and Reggio Emilia, Italy - took place on February 3, 2021. The two companies will be legally integrated…

11/04/2020 - Oliver Hagenlocher - Press

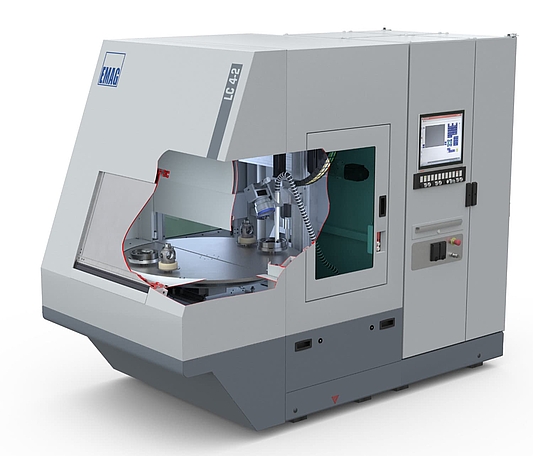

LC 4-2 Laser Cleaning Machine: Focused on Fast Cleaning Processes and Optimizing Component Surface QualityThe need for industrial cleaning processes is not uncommon – many parts are contaminated with substances including oil and adhesives, or have undesired layers of oxide, rust, phosphate, or paint that needs to be removed before additional machining…

10/05/2020 - Oliver Hagenlocher - Press

Red Dot Award for EMAG: AI solution EDNA perfects networking of industrial productionThe factories of the future are connected—in every respect: Machines communicate with each other regarding errors or required maintenance, while providing essential information to production planners that can control the machines from one central…

09/30/2020 - Oliver Hagenlocher - Press

Using scroll-free turning to optimize the production of rotor shaftsThe automotive industry is in transformation and production planners are placing increasing importance not only on new components, but also on new manufacturing methods. After all, the increased demand for electric vehicles is also leading to higher…

09/14/2020 - Oliver Hagenlocher - Press

The CI machine from EMAG ECM: A Highly Effective Solution for Deburring Complex ComponentsAutonomous steering and brake systems, hydro-pneumatic chassis, or radically improved gas mileage – these buzzwords represent a technological change that is triggering a domino effect in the automotive and other industries. An increasing number of…

09/07/2020 - EMAG GmbH & Co. KG - Press

VLC 200 GT from EMAG: Combining technologies to machine state-of-the-art transmission componentsIt is no secret that e-mobility is a growing market. A current study by the consulting firm Strategy Analytics, predicts the production output of “electric vehicles” will increase to 25% of the global market by 2025. It should be noted that the study…

09/01/2020 - Oliver Hagenlocher - Press

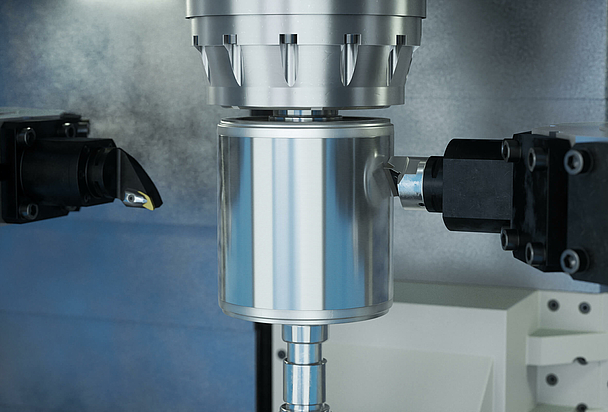

VMC 450-5 MT Turning/Milling Center – Five Axes for Dramatically Shorter Machining Processes in the Production of Large PartsLarge components and complex geometries—in heavy machining, this combination is far from rare and is always synonymous with a high expenditure of time and rising costs. A primary reason for this is that the variety of machining processes required,…

08/24/2020 - Oliver Hagenlocher - Press

HLC 150 H by EMAG KOEPFER: All-round gear-cutting solution for more flexibility and lower costMore than ever, planners in the automotive industry are faced with the crucial challenge of flexibility in production technology. Manufacturers continually need to cope with modified ranges of components. For instance, the geometry can change very…

08/17/2020 - Press

Lightweight Design for Commercial Vehicles: EMAG LaserTec is developing a holistic production solution for large truck differentialsWhen the catch phrase “lightweight design” is used for the automobile production, it typically refers to passenger cars, rarely commercial vehicles. However, there is an enormous amount of potential for weight reduction and cost savings when…

08/10/2020 - Press

Production system by EMAG: High-performance solutions for differential casesThe worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality…

07/16/2020 - Oliver Hagenlocher - Press

VLC 350 GT from EMAG: The perfect solution for the future of transmission and engine productions chucked partsWhat will the cars on the street look like in the future? A new study by the Boston Consulting Group forecasts a mix of gasoline and diesel engines (48 percent), hybrid vehicles (33 percent) and completely electric (19 percent). For OEM’s and supply…

06/15/2020 - Oliver Hagenlocher - Press

VL 1 TWIN from EMAG: Drastically Lower Unit Cost for Bevel GearsBevel gears found in passenger vehicles are mass-produced. Supply companies produce these gears, essential for differentials, by the million—and it’s no wonder, since there are four of these in every differential. The number of all-wheel-drive…

06/09/2020 - Press

EMAG Announces Expansion with the Opening of EMAG Charlotte!Beginning June 1, 2020, EMAG will be expanding its operation in the United States by opening an additional office, EMAG Charlotte, in Charlotte, NC. With this addition, current and prospective customers located in the southeastern portion of the…

05/14/2020 - Oliver Hagenlocher - Press

W 11 CNC from EMAG Weiss—Manual CNC-Supported External and Internal Cylindrical GrinderThe EMAG Group is breaking new ground with the W 11 CNC cylindrical grinder from EMAG Weiss. The company from Salach, near Stuttgart, Germany, is primarily known for its turning and grinding machines intended for high-volume production. With its W 11…

02/27/2020 - Oliver Hagenlocher - Press

EMAG Oilfield Technology: The World Premiere of EMAG’s In-Process Non-Contact Thread Measuring SystemAccording to the 2018 energy study of the German Federal Institute for Geosciences and Natural Resources (BGR), with a share of 30.5% of the world’s primary energy consumption, oil remains the most important source of energy.

However, global trade…

02/24/2020 - Oliver Hagenlocher - Press

EMAG Receives “Outstanding Supplier” Award from SisamexThe EMAG Group and Sisamex, a member of the Mexican Quimmco Group, have been production partners for over 20-years. At its plants in Monterrey, Sisamex produces a large variety of workpieces for trucks, agricultural and utility vehicles for many…

01/15/2020 - Oliver Hagenlocher - Press

EMAG Acquires CNC-Technik Weiss GmbH Headquartered in Neckartailfingen, GermanyThe EMAG Group is expanding its technology range in the field of grinding with cylindrical grinding technology from WEISS. “We are extending our range of products in the area of high-output and high-precision cylindrical grinders with grinding…

01/13/2020 - Oliver Hagenlocher - Press

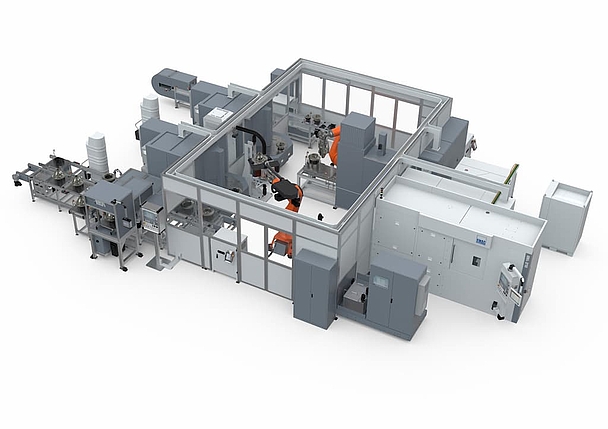

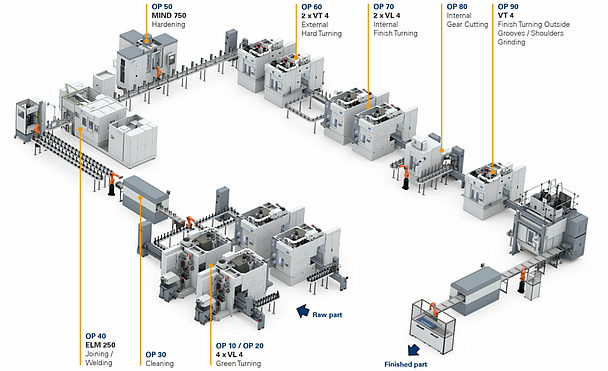

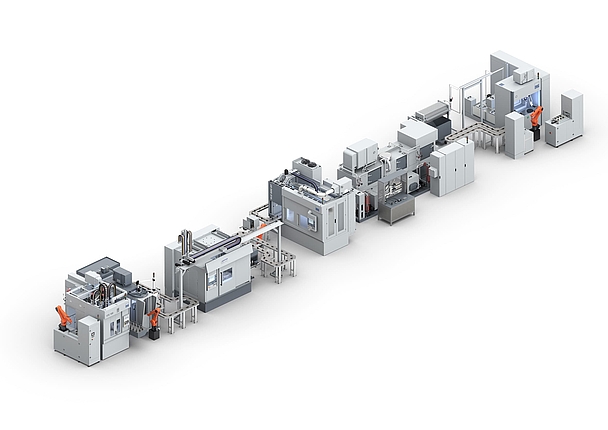

The New EMAG Systems: EMAG provides complete turnkey solutions from a single sourceThe production of comprehensive manufacturing solutions from a single source is the main requirement for many mechanical engineering production planners. Typically, a general contractor would be responsible for the development of a complex line of…

12/02/2019 - Oliver Hagenlocher - Press

Production System by EMAG: Lightweight Rotor Shafts Machined with End-to-End Production SystemsA large number of studies are predicting rapid growth in e-mobility. The latest sales figures confirm the trend: According to the Center of Automotive Management, sales of electric cars in China and the USA increased dramatically last year. In…

11/07/2019 - Oliver Hagenlocher - Press

R 300 Hobbing Machine from EMAG Richardon: HKS Dreh-Antriebe Invests in High-Efficiency Gear Cutting ProcessesRotary actuators are jacks-of-all-trades: They are implemented whenever an object must be rotated or swiveled—this is necessary during the production of utility vehicles, ships, machines, power plants, and production areas. This broad range of uses…

10/14/2019 - Oliver Hagenlocher - Press

EMAG Production System: Perfecting the Finish-Machining of Turbocharger ShaftsThe production of turbochargers is one of the most demanding tasks in automotive engineering: High-strength materials, precise geometric requirements, large quantities and price pressure are key challenges for OEMs and suppliers. The continual…

08/23/2019 - Oliver Hagenlocher - Press

Laser Cleaning Machine of EMAG LaserTec: LC 4-2 Laser Cleaning Machine for implementation in Manufacturing Lines or as a Standalone MachineEMAG LaserTec is known first and foremost for highly productive laser welding systems. The focus is indeed on the word “system”: In addition to the actual welding process, steps that occur upstream or downstream of the welding are frequently…

08/20/2019 - Oliver Hagenlocher - Press

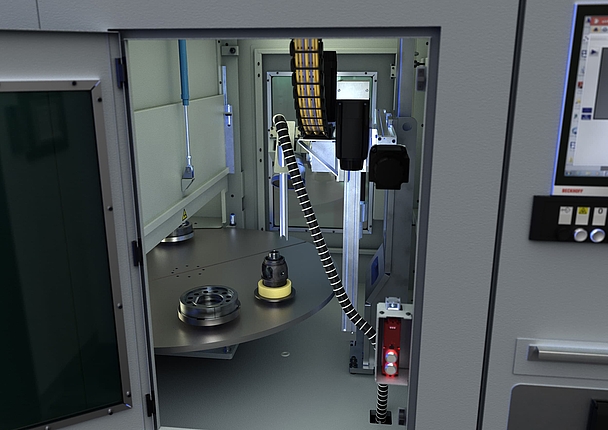

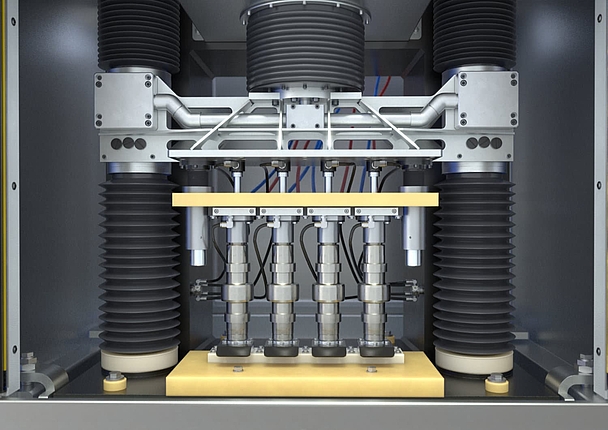

PI 800—Modular ECM / PECM Machine: Completing complex machining tasks very efficiently with an electrochemical processAnyone who has had a closer look at the ECM process knows that it is an innovative technology. In order to make manufacturing with PECM even more accessible, EMAG ECM, headquartered in Gaildorf, near Schwäbisch Hall in Germany, has developed a new…

08/12/2019 - Oliver Hagenlocher - Press

The new MIND-L 1000 from EMAG eldec: Lower cost of investment and increased productivity in induction hardeningPrecisely timed cycles, extremely accurate heating patterns and perfect integration in the production process—the advantages that induction hardening provides propel the implementation of the process in many application areas in the automotive…

08/07/2019 - Oliver Hagenlocher - Press

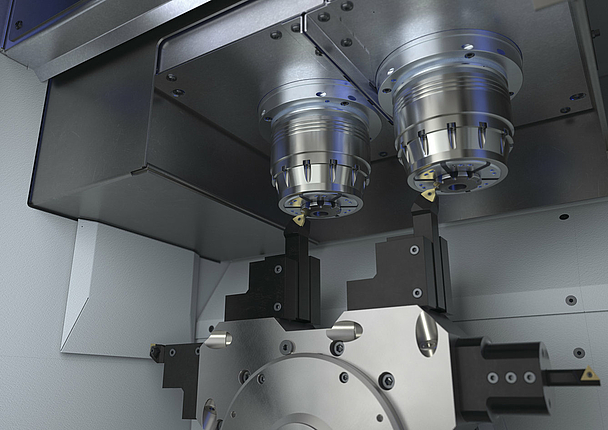

New DUO Machine for Series Production: The VL 5 DUO from EMAG delivers a boost to the Production of Powertrain Components up to 250 mmThe success story of DUO machines from the EMAG Modular Solutions product family keeps on going. At the EMO in Hanover, EMAG will present the latest expansion stage of the DUO series, the VL 5 DUO. What can users expect from the new machine? In a…

08/06/2019 - Oliver Hagenlocher - Press

EMO 2019 – Complete Production Solutions with the VL 1 TWIN: Massively reduce unit costs for planetary and bevel gearsCost pressure, high quality requirements and demand for huge output volumes—extremes collide in automotive transmission manufacturing. While meeting these demands, production quantities will also projected to continue to rise in the coming years. The…

07/02/2019 - Oliver Hagenlocher - Press

EMAG at the EMO 2019 in Hanover: The Sequel to a Successful Event ConceptWhat does the automotive future hold? This question is one way you could briefly summarize the motto of the EMAG Group's 2019 Technology Forum held at its headquarters this May.

The technology forum is traditionally held in the same year as the EMO…

06/05/2019 - Oliver Hagenlocher - Press

Solid-State Versus Gas Lasers – Modern Laser Production Technology for Powertrain ComponentsEven a few years back major manufacturers utilized standard CO2 lasers in factories for welding applications. Massive systems installed in separate rooms away from the actual production process supplied the energy for what, at the time, was…

05/29/2019 - Oliver Hagenlocher - Press

Experts advised about the revolution in the automotive industryBuzzwords such as “e-mobility,” “autonomous driving” and “big data” outline a fundamental shift in the global automotive industry that comes with far-reaching changes to production—constituting a major challenge for the underlying mechanical…

05/20/2019 - Press

EMAG wins the “Axia Best Managed Companies Award”Strategic vision, capacity to innovate, sustainable management culture and good corporate governance—the “Axia Best Managed Companies Award” sets expectations high for participating businesses. This year, the organizers from the consulting firm…

02/06/2019 - Oliver Hagenlocher - Press

EMAG Automation becomes EMAG LaserTec: Driving laser welding and joining technology with a new nameEMAG laser welding technology has been an impressive success story for years: The system ensures efficient light construction and lower component costs in the manufacture of numerous vehicle components. The relevant turnkey production systems are…