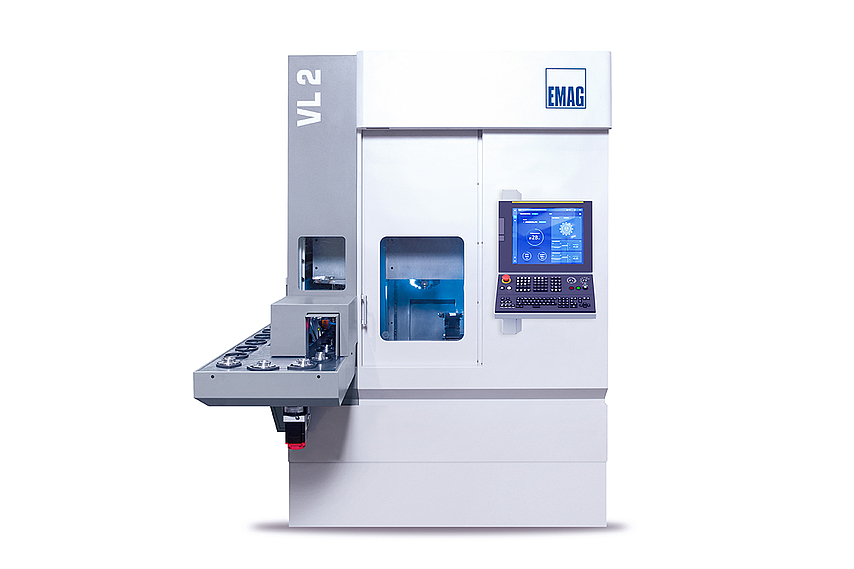

Modular – Chucked Components – VL/VM

VL 2

- Workpiece dia., max.: 100 mm | 4 in

- Workpiece length, max.: 150 mm | 6 in

- Chuck dia., max.: 160 mm | 6.5 in

VL 2 – Vertical Pick-Up Turning Machine for Chucked Components up to 100 mm in Diameter

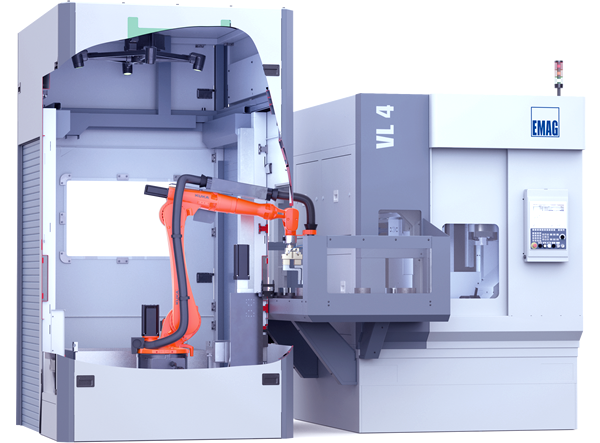

A stable machine structure, dynamic axes and ease of operation - these are the outstanding features of the VL series vertical turning machines. Based on a completely new modular machine concept, VL 2 vertical lathes make it possible to utilize various production technologies for soft and hard machining with integrated automation and a pick-up spindle, all while providing the best value for the investment.

VL 2 Turning Machine for Efficient Machining with Top Precision

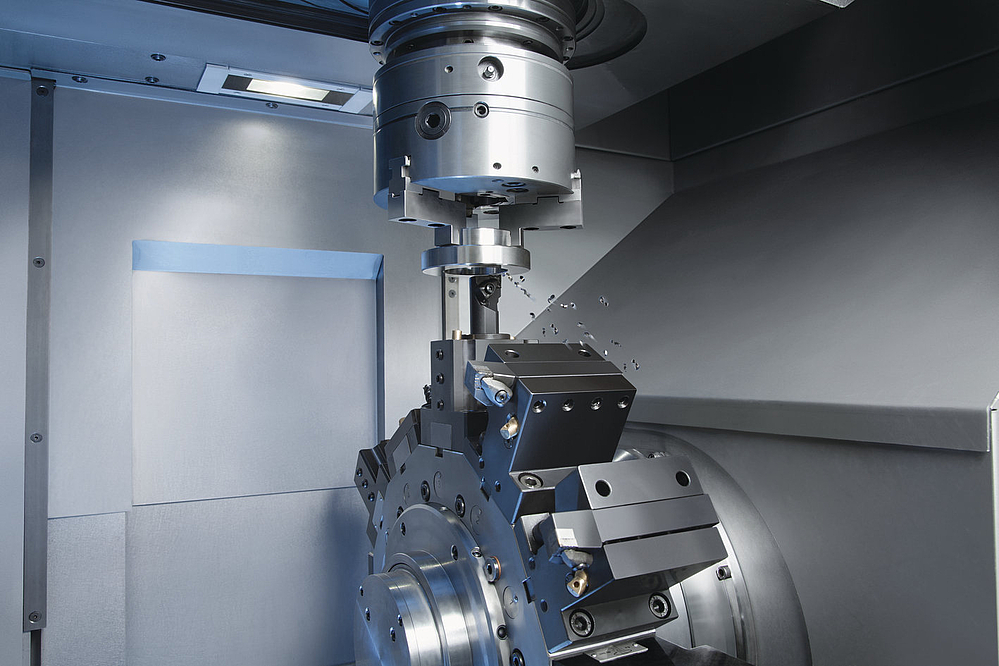

Three axes + turret with up to twelve driven tools + automation.

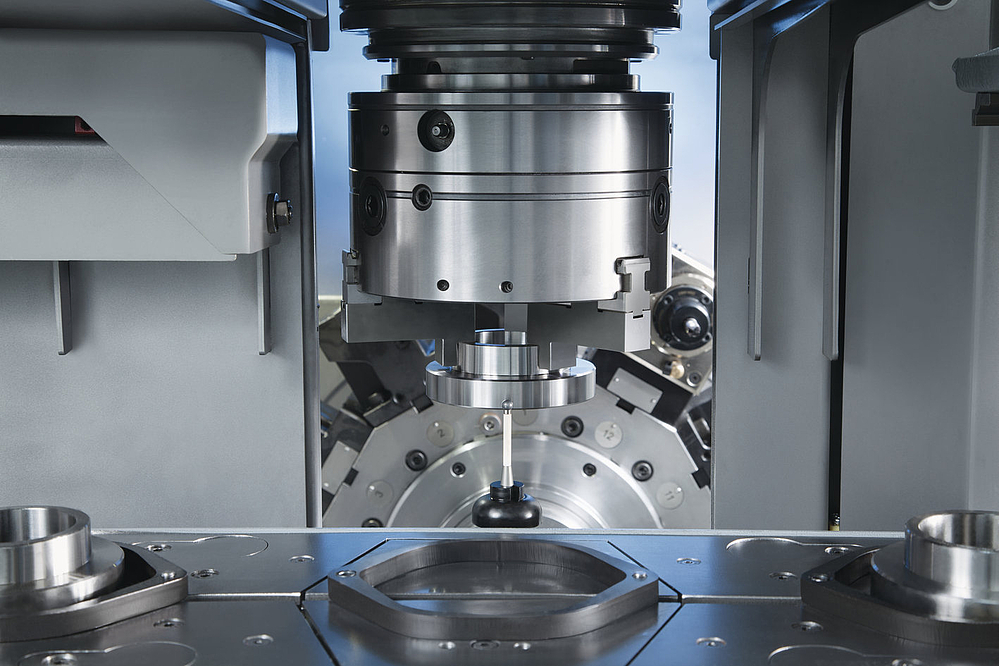

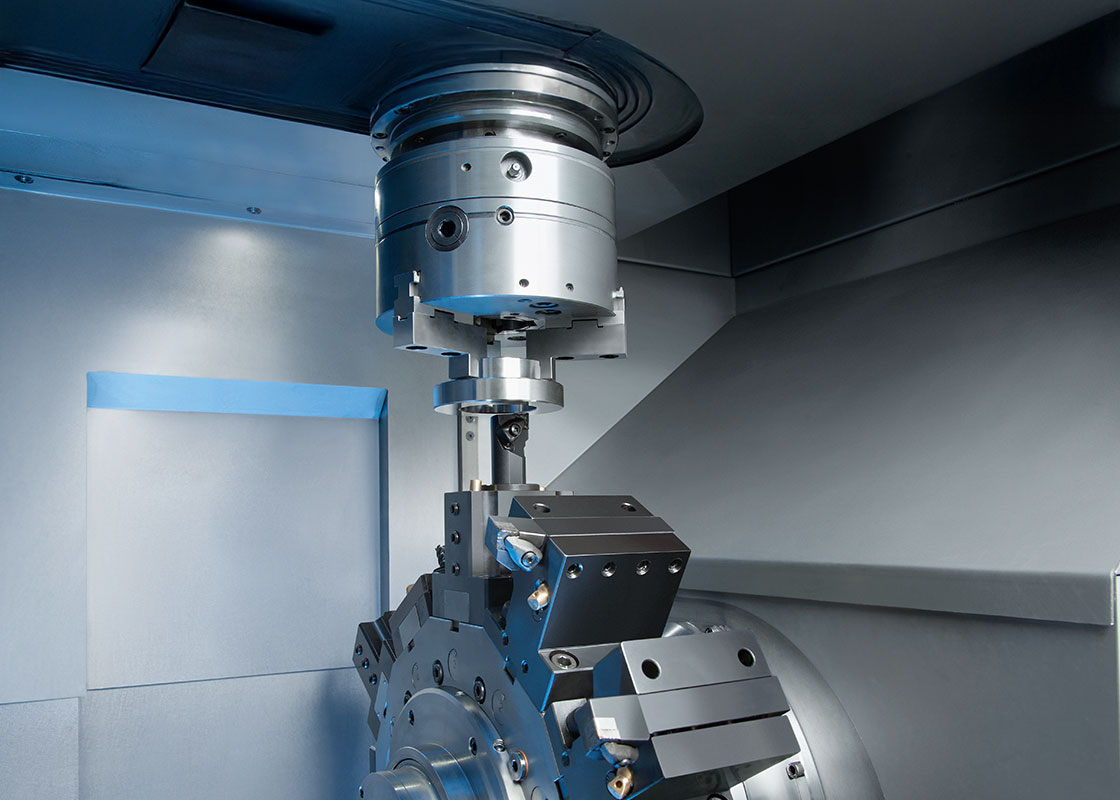

The basic VL 2 machine, a three-axis inverted vertical turning machine, has an eye-catching design. The lathe's basis is the machine body made of MINERALIT® polymer concrete. The working spindle is mounted on the front of the machine bod y on a compound slide, which completes movements in the X- and Z-axes. The turret is located below the working spindle and can hold up to twelve turning or driven tools. In addition, the VL 2 cnc turning machine can be equipped with a Y-axis in the turret.

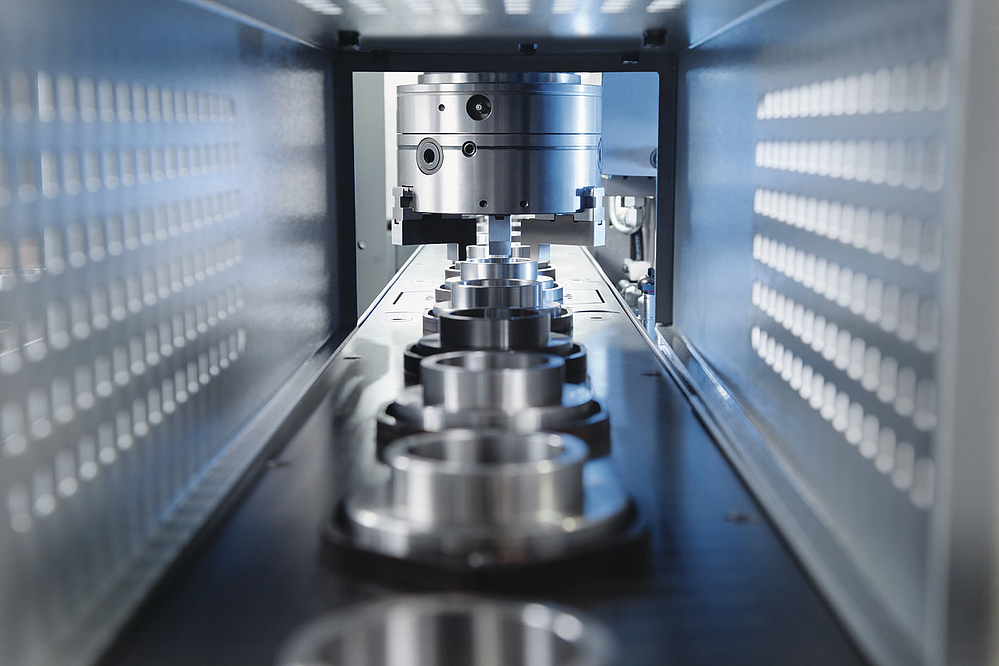

The lathes are also ideally designed for use in assembly line production, as the VL 2 turning machines can be linked with simple automation components, such as conveyors, flip-over units, and changers.

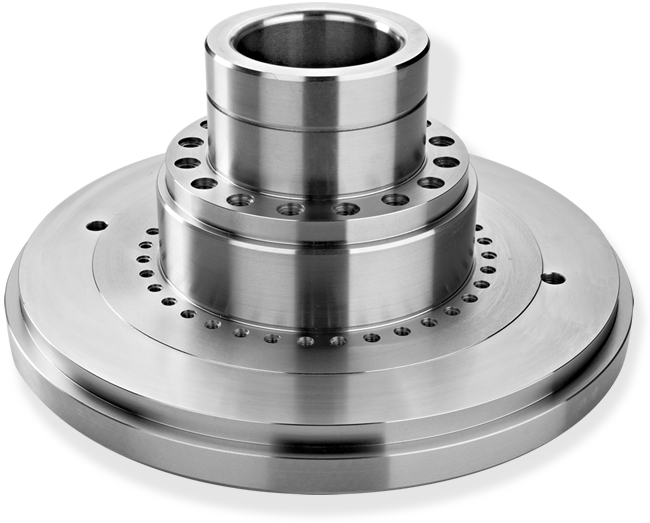

Workpieces that can be machined with the lathe include flanges and gears. Here, combining the vertical lathes with other modular machines offers an efficient way to implement an assembly line for gears, for example. The cnc turning performed by the VL 2 is complemented by a subsequent process on a VL 4 H for the tooth hobbing and the use of a VLC 100 C for chamfering.

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VL 2

- Simple automation concept = high availability

- Integrated automation, automatic workpiece changing

- Short distances for machining and loading, and therefore very short cycle times

- High strength and excellent damping thanks to the machine body made of MINERALIT® polymer concrete

- Ideal chip flow conditions

- Small footprint, 5 m² machine installation area

- All service units are freely accessible

- Simple tool changing, just 270 mm distance to tool turret

Workpieces

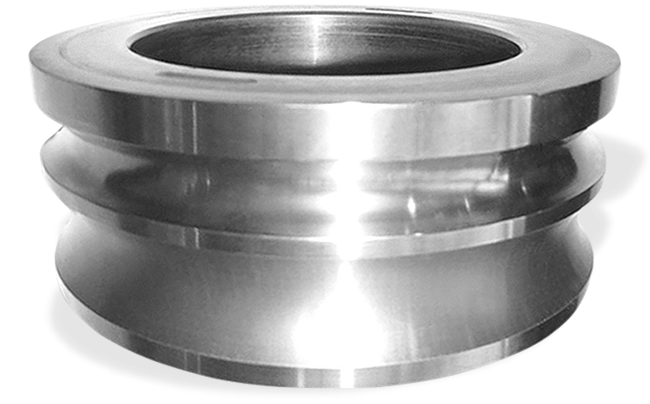

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Technical Data

Workpiece dia., max.

100 mm

4 in

Workpiece length, max.

150 mm

6 in

Chuck dia., max.

160 mm

6.5 in

| Workpiece dia., max. |

mm

in |

100

4 |

| Workpiece length, max. |

mm

in |

150

6 |

| Chuck dia., max. |

mm

in |

160

6.5 |

| Swing diameter |

mm

in |

210

8.5 |

| X-axis travel |

mm

in |

650

25.5 |