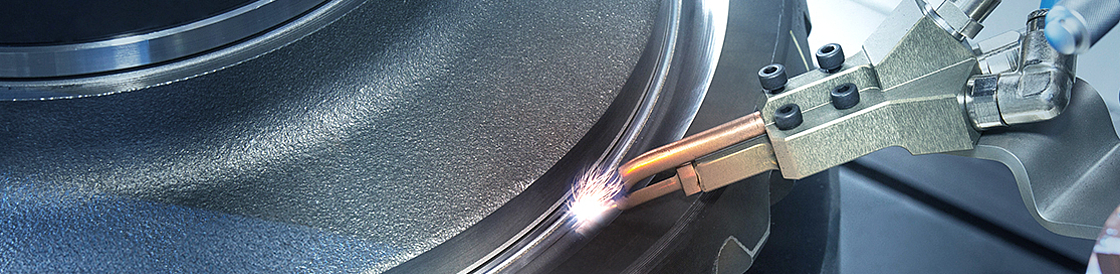

Laser Welding Machines for High-Efficiency Production of Powertrain Components

EMAG LaserTec supplies laser welding machines and complete systems for the production of transmission components of all kinds. Its laser welding systems, and their developed processes, have become industry standards.

Overview Laser-Welding Machines from EMAG

(5) machines found