Customized VLC

VLC 400

- Workpiece dia., max.: 400 mm | 15.5 in

- Workpiece length, max.: 300 mm | 12 in

- Chuck dia., max.: 500 mm | 19.5 in

VLC 400 Vertical Turning Machine for the Productive Machining of Large Chucked Parts

The VLC 400 is a vertical turning machine that offers great versatility for the manufacture of chucked parts thanks to its modular structure and the many technologies to choose from. It allows machining of chucked parts up to 400 mm in diameter.

VLC 400 – The Vertical Production Lathe for Large Chucked Parts

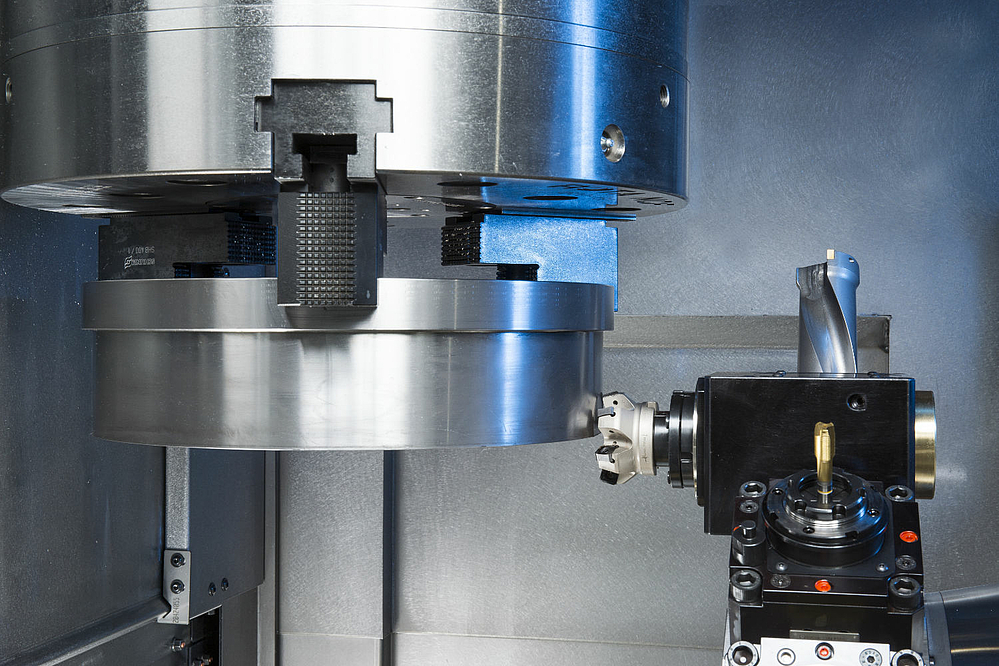

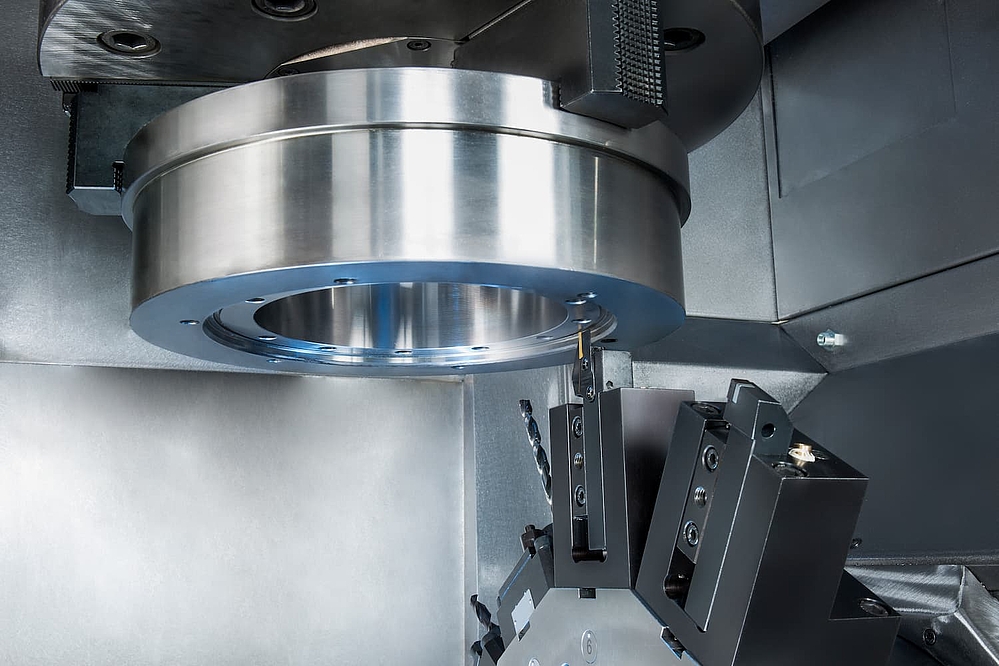

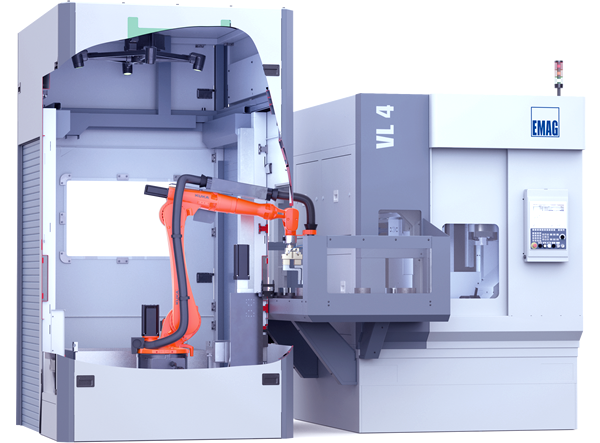

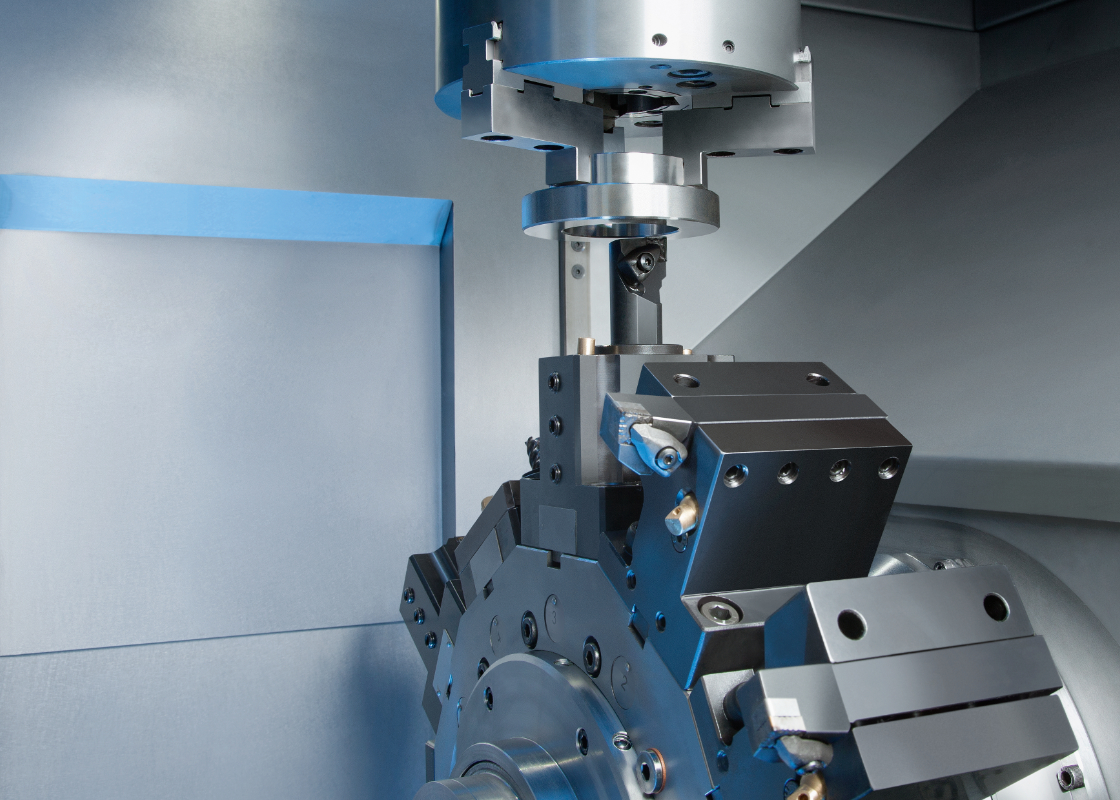

The VLC 400 vertical pick-up turning machine gives the user nearly unlimited equipping options with machining technologies. Whether turning or milling, drilling or grinding – the user has access to the wide technology portfolio of the EMAG Group. This makes it possible to realize even complex manufacturing objectives using one or more machines from the VLC series. The largest machine in the VLC series, the VLC 400 is designed for chucked parts up to 400 mm in diameter.

The core of the VLC vertical turning machine is a base made from Mineralit® polymer concrete. It ensures low-vibration machining for long tool lifetimes and very high machining quality. High productivity and short chip-to-chip times are the result of the machine's top power combined with the pick-up function of the drive spindle. With this function the machine loads itself, taking parts from the integrated conveyor belt (likewise fully configurable) and feeding them into the machining area.

The working spindles have an especially high rigidity: Short distances between bearings, high-precision separable bearings in a tandem-O-tandem arrangement, and support bearings at the spindle end permit turning processes with micrometer accuracy.

A measuring probe is also available, allowing an inspection process to be integrated into the machining sequence. The measuring probe is installed outside the machining area of the turning machines and checks the workpiece while it is still clamped. Consistently high quality is thus ensured for high-volume production runs.

Advantages VLC 400

- Machining of chucked parts with a standardized machine concept

- Small footprint (chaku-chaku or close linear arrangement) for reduced floor space costs with multiple options for machine positioning

- Option of simple interlinking via central infeeding and outfeeding conveyors and pick-and-place/turnover units with flexibility for the future, lower automation costs, and shorter tooling times

- Integrated automation with no additional costs (interfaces, etc.)

- Short distances for part transport optimally minimize non-productive times

- Common parts strategy and spare parts management for low life cycle costs

- User-friendliness (easily accessible machining area) offers faster setup, safe operation and the option of compact alternative layouts

- High energy efficiency for lower energy costs

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Industry 4.0

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

400 mm

15.5 in

Workpiece length, max.

300 mm

12 in

Chuck dia., max.

500 mm

19.5 in

| Workpiece dia., max. | mm in | 400 15.5 |

| Workpiece length, max. | mm in | 300 12 |

| Chuck dia., max. | mm in | 500 19.5 |

| Swing diameter | mm in | 520 20.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact