Universal Cylindrical Grinding Machines

WUG 21

- Workpiece dia., max.: 640 mm | 25 in

- Workpiece length, max.: 1,500 mm | 59 in

- Center height: 320 mm | 12.5 in

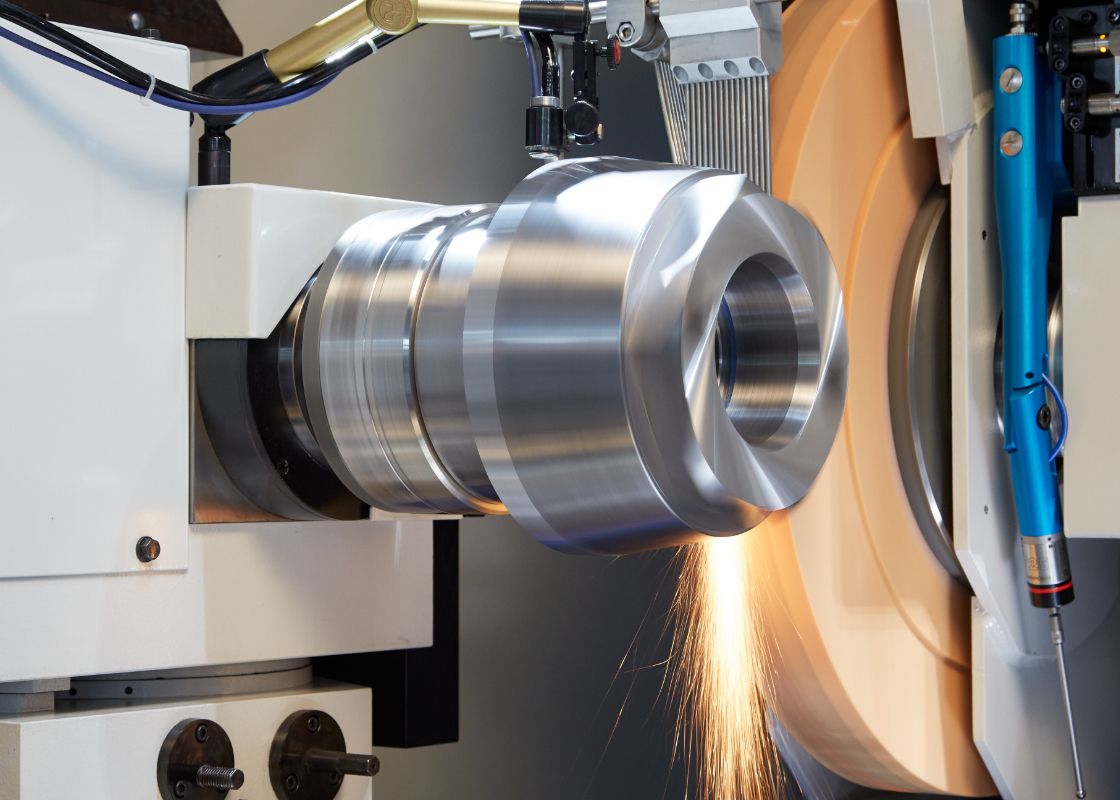

WUG 21—CNC Universal Cylindrical Grinder for Single Parts, Prototypes and Small Series Production

Manual or fully automatic? With the WUG 21 CNC universal cylindrical grinder, you don’t have to decide! You’ll be able to switch between manual and fully automatic grinding with just a push of a button. Owing to this feature, as well as, the vast equipment catalog, the WUG 21 cylindrical grinder is the perfect machine for small batches, single parts, and prototype manufacturing.

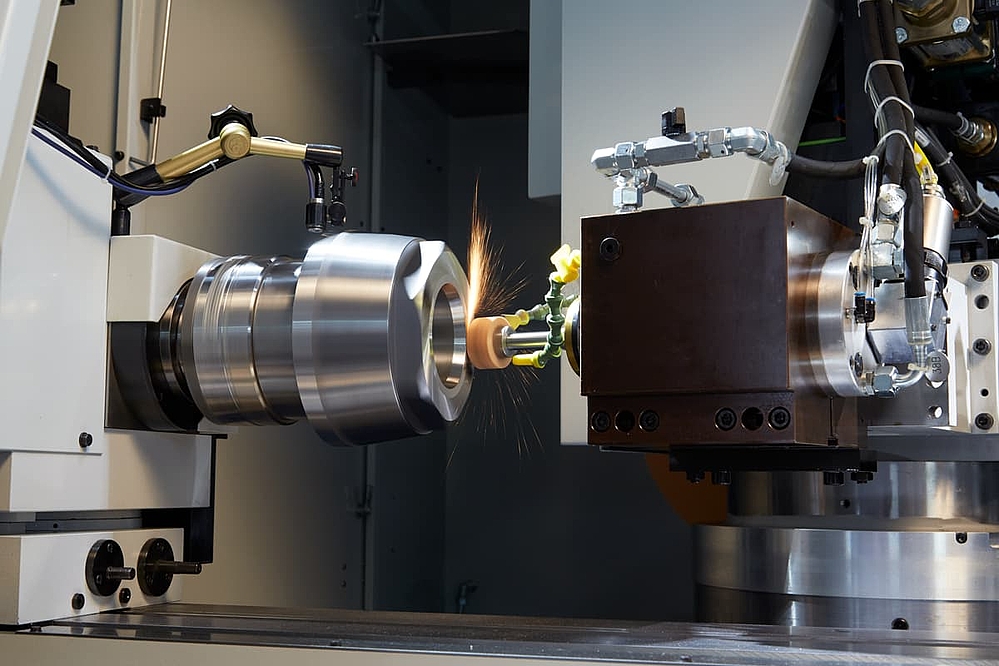

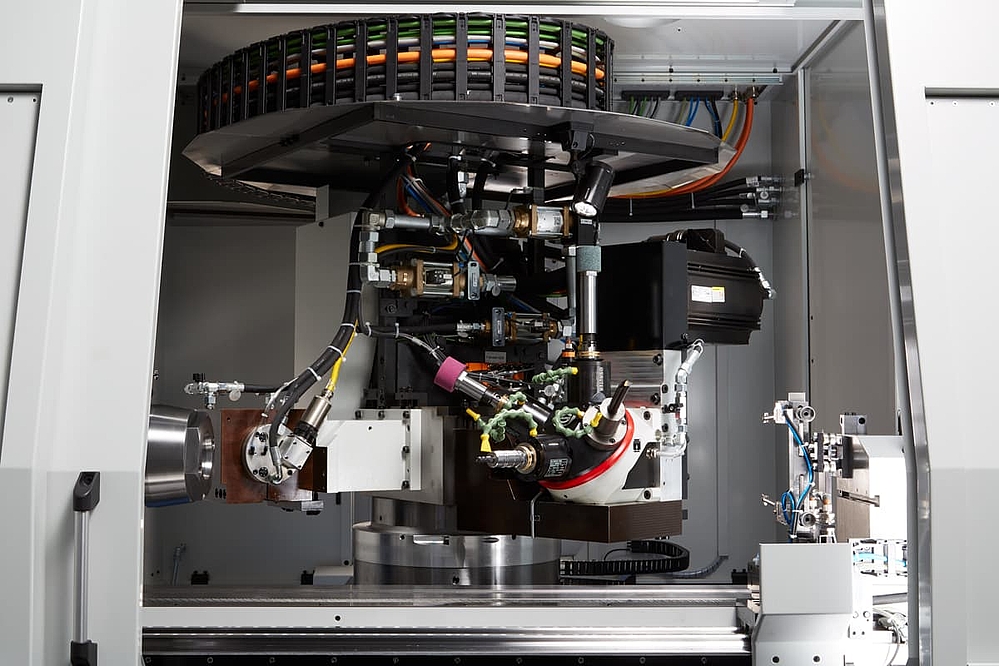

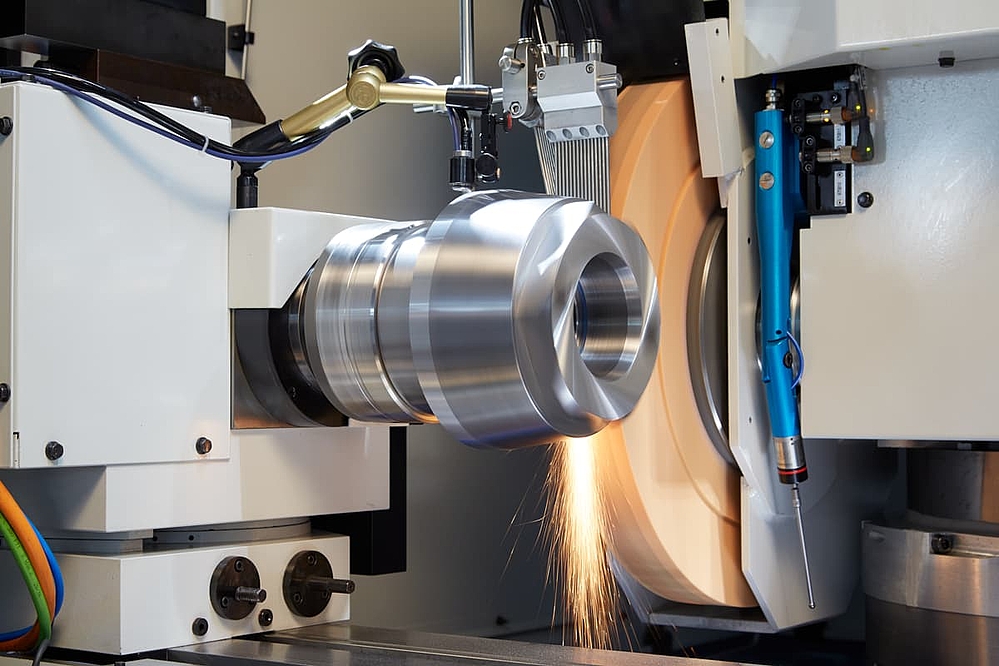

Flexible External and Internal Grinding with the WUG 21 Universal Cylindrical Grinder

The vast equipment catalog for the WUG 21 CNC universal cylindrical grinder includes more than 25 different variants of the grinding headstock mount, which enable a wide variety of combinations of external and internal grinding spindles. The grinding spindle can be equipped with a B-axis for fast and highly accurate swiveling. In addition to the grinding spindles, there is an option for integrating a quadruple turret that can be equipped alternatively with turning tools (for hard pre-turning) or additional internal grinding spindles - allowing for the implementation of a variety of machining scenarios. The WUG 21 universal cylindrical grinder allows for grinding lengths of 650/1,000/1,500/2,000 mm (26/39/59/79 in) and tip heights of 200/250/320 mm (8/10/13 in).

The workpiece headstock with its MK4/MK5/MK6 spindle socket and a precision spindle bearing with radial running of less than 0.5 μm turns out to be just as flexible. The speed can be adjusted continuously up to 1,000 rpm and allows for an on-the-fly workpiece weight of 100 – 250 kg (220 – 551 lbs) (depending on configuration).

The perfect complement to this is the tailstock with an MK4 quill socket, also for a workpiece weight between tips of 250 kg (551 lbs). In automatic mode, a modern, fast, and grinding-oriented control unit with a Windows interface, as well as, USB and network ports ensures simple program management for optimal processes. Programming is performed using a dialog-based interface or optionally in DIN/ISO programming. All common grinding cycles are provided as standard.

Options:

- In-process gaging control

- Automatic balancing

- GAP sensors

- Transformation B-axis

- 2D/3D non-round grinding

- Rotating dressing wheel

- High-frequency spindle in various versions

- Touch probe for active length positioning

- Automation with loading gantry or robot

Advantages WUG 21

- Switch between manual and automatic mode with just the push of a button

- Highly flexible machine system owing to numerous options

- Modern and fast control unit geared for grinding

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Technical Data

Workpiece dia., max.

640 mm

25 in

Workpiece length, max.

1,500 mm

59 in

Center height

320 mm

12.5 in

| Workpiece dia., max. | mm in | 640 25 |

| Workpiece length, max. | mm in | 1,500 59 |

| Center height | mm in | 320 12.5 |

| Grindable diameter | mm in | 360 / 500 14 / 19.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact