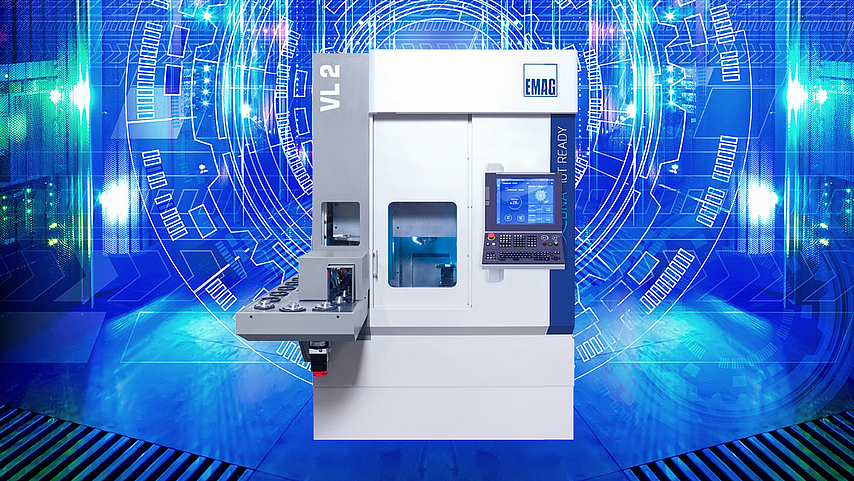

Modular Shaft Machining VT

VT 2

- Workpiece dia., max.: 100 mm | 4 in

- Workpiece length, max.: 400 mm | 15.5 in

- Chuck dia., max.: 160 mm | 6.5 in

Maximum Efficiency in Shaft Production – VT 2 Lathes

Short cycle times, high precision and safe processing are among the outstanding attributes of shaft machining on the turning machines of the VT series.

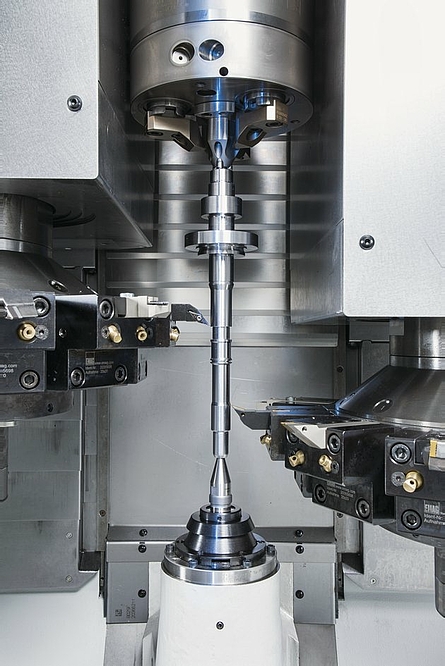

These lathes literally turn the classical horizontal machining process on its head.

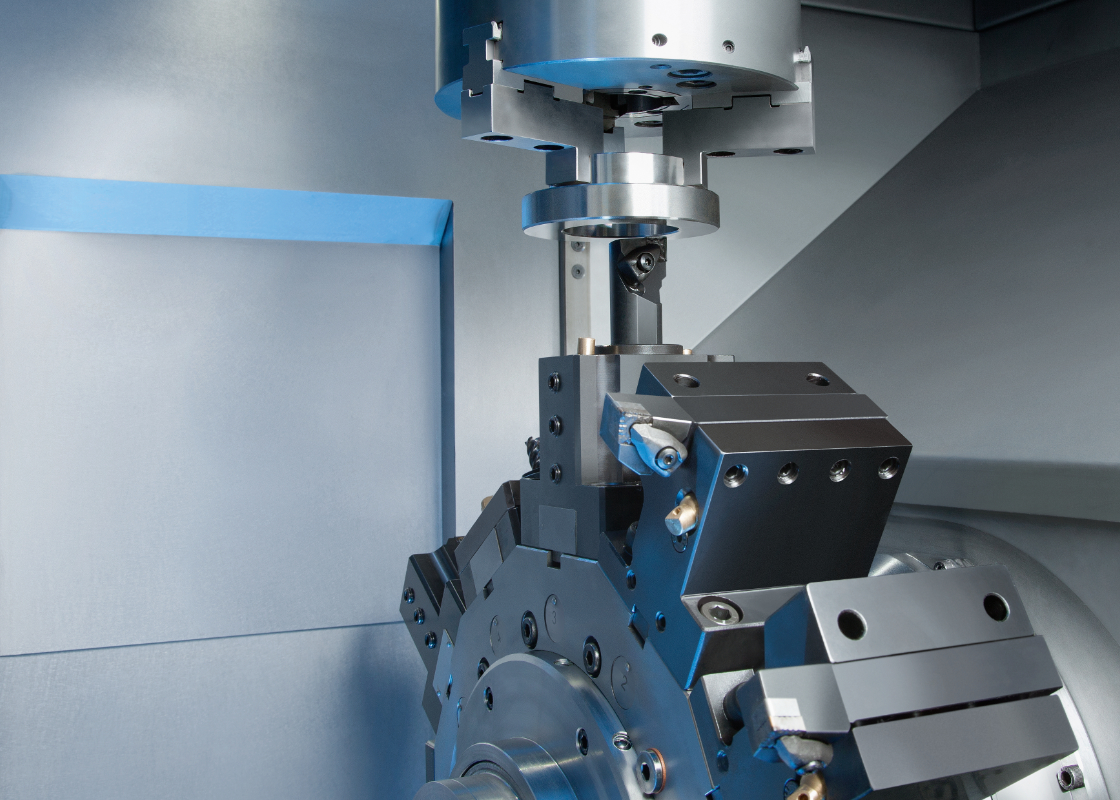

Modular Lathe for Vertical 4-Axis Shaft Machining

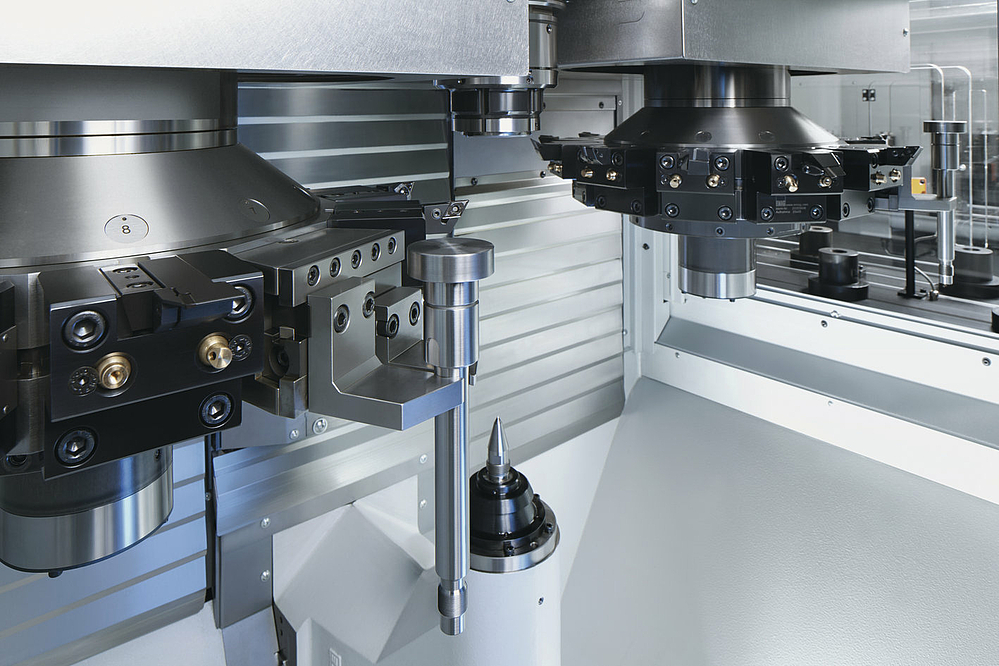

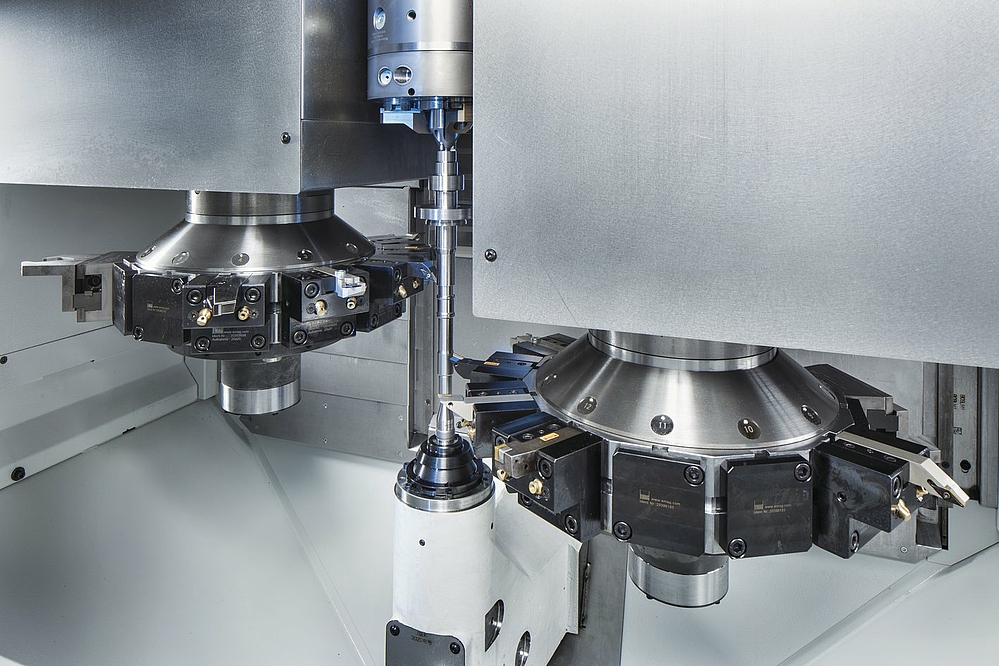

Four axes, short travels, a powerful main spindle – these are the strengths of the VT 2 turning machine. The use of a “two-sided” process massively reduces machining times on VT lathes, allowing for large component batch sizes to be manufactured quickly.

Flexibility is guaranteed with the use of two tool turrets, each with eleven stations, all of which can be equipped with turning tools and driven tools. Automation is fully integrated on these lathes, as the turret loads and unloads workpieces into the machining area. While one gripper, occupying the twelfth position of the turret, conveys a new raw part into the machine, the other removes the finished component. This changeover process takes only six seconds, depending on the workpiece.

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VT series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VT Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VT 2

- Shorter cycle times through four-axis machining

- Less investment required in sensors, as the machine axes are direct driven and the machine’s control system is of the latest design

- Short setting and resetting times owing to great machine accessibility and operator friendliness

- Less operator intervention (tailstock and steady are CN-controlled, the turrets can be accessed directly)

- The vertical construction of the machine and the resulting free chip flow prevent the creation of chip clusters

- Less expense for automation and peripherals

- Raw-part and finished component storage form an integral part of the machine

- Reduced idle times through cycle time-concurrent loading and unloading

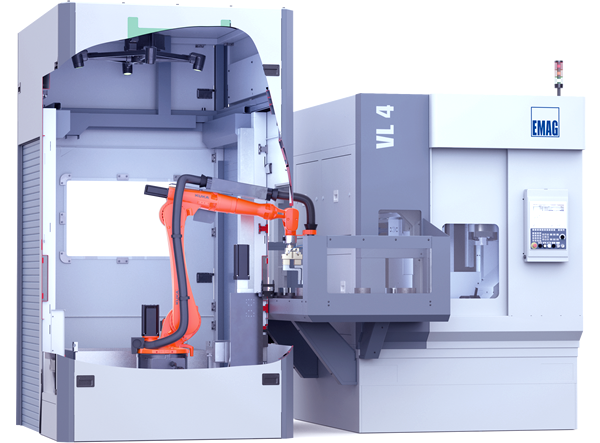

- The machine can be used as a stand-alone or in a production line

- The compact, vertical construction of the machine makes for a small footprint

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Digitalization

Digitalization @ EMAG - The Future is Connected

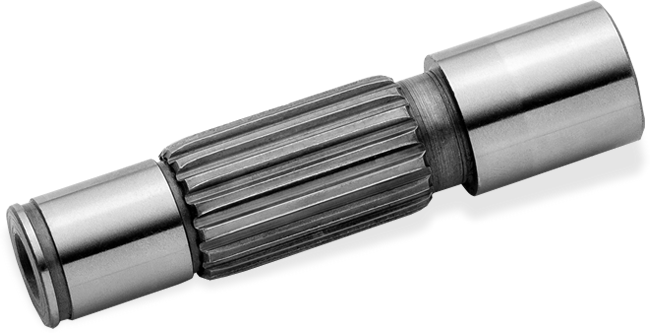

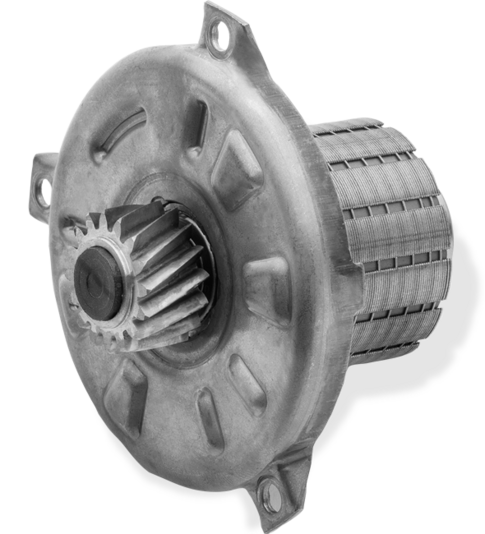

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

100 mm

4 in

Workpiece length, max.

400 mm

15.5 in

Chuck dia., max.

160 mm

6.5 in

| Workpiece dia., max. | mm in | 100 4 |

| Workpiece length, max. | mm in | 400 15.5 |

| Chuck dia., max. | mm in | 160 6.5 |

| Swing diameter | mm in | 210 8.5 |

| Gripper diameter, max. | mm in | 63 2.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact