Customized VLC

VLC 300

- Workpiece dia., max.: 300 mm | 12 in

- Workpiece length, max.: 250 mm | 10 in

- Chuck dia., max.: 400 mm | 15.5 in

Pick-up turning center VLC 300 for advanced machining of chucked parts

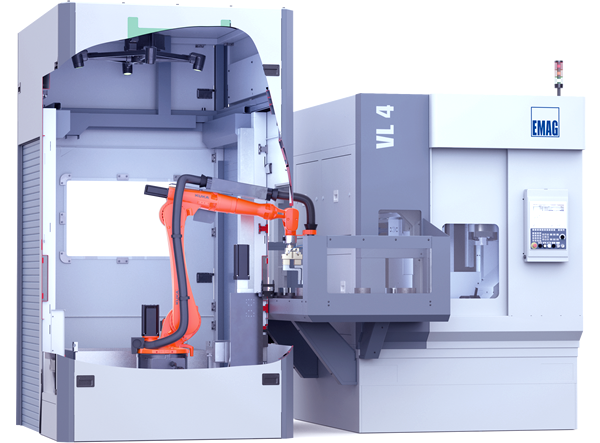

The VLC 300 is a pick-up turning machine that can be configured for a wide variety of applications. Especially ideal for machining large workpieces, it allows large chucked parts to be produced with high productivity and high precision.

VLC 300 – The Pick-Up Turning Machine With More Than Just Turning

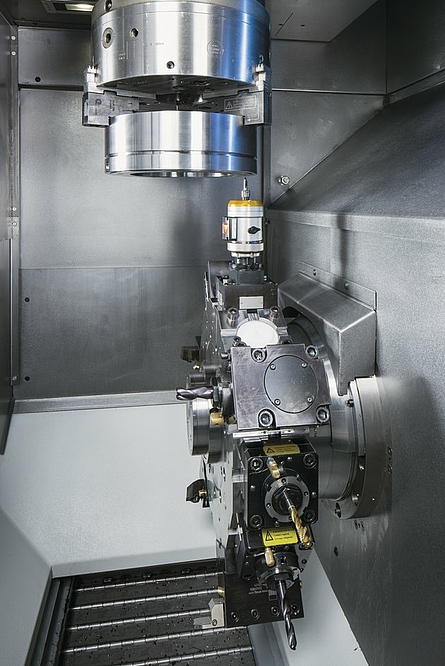

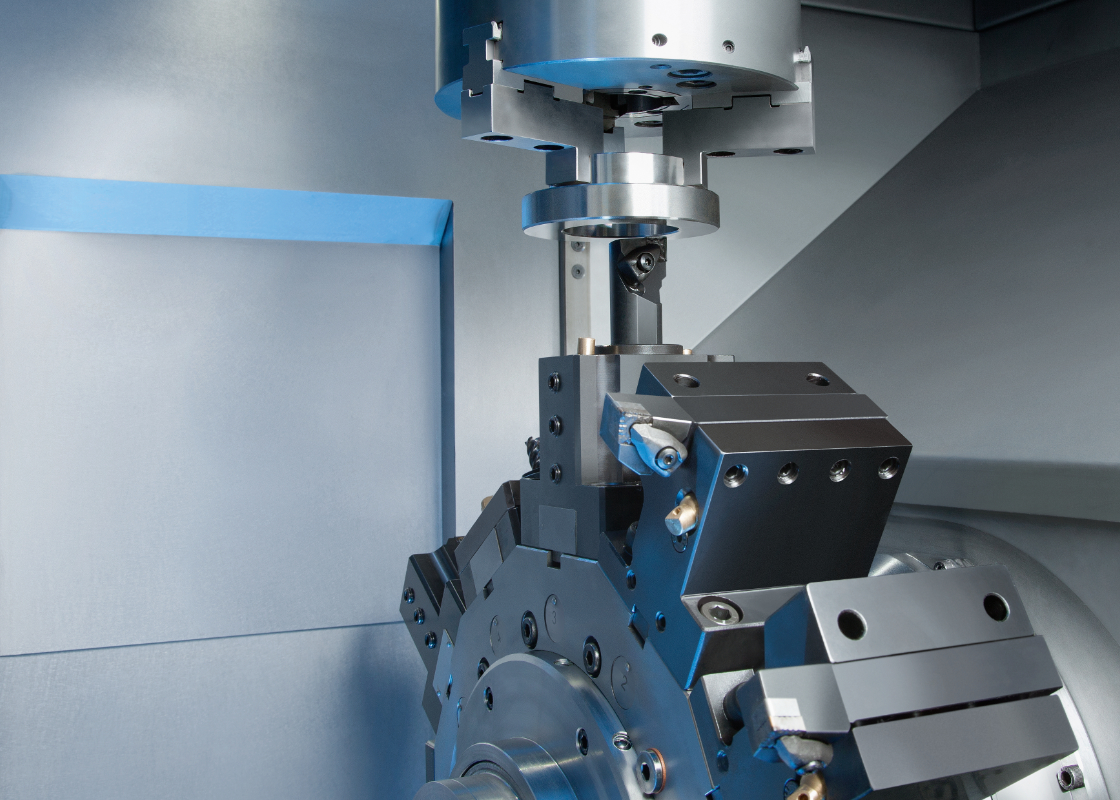

The VLC 300 is designed for large workpieces up to 300 mm in diameter. The pick-up turning lathe makes it possible to utilize a range of machining technologies flexibly. This vertical turning machine is extremely compact and features powerful drives in its spindle and axes, ensuring adequate power at all times. Its highly flexible tooling options and powerful working spindle are supplemented by the integrated automation system with a pick-up spindle which makes the VLC 300 into a high-productivity production lathe.

Low-vibration machining is made possible by the Mineralit® polymer concrete body. This ensures long tool life and very high machining quality. The main spindle is fastened to the front of the machine base by means of a compound slide rest, allowing dynamic motion along the X-axis and Z-axis. A Y-axis in the tool turret is available as an option.

The VLC 300 is ideal for assembly-line use with a wide range of automation components for perfect interlinking.

Advantages VLC 300

- Machining of chucked parts with a standardized machine concept

- Small footprint (chaku-chaku or close linear arrangement) for reduced floor space costs with multiple options for machine positioning

- Option of simple interlinking via central infeeding and outfeeding conveyors and pick-and-place/turnover units with flexibility for the future, lower automation costs, and shorter tooling times

- Integrated automation with no additional costs (interfaces, etc.)

- Short distances for part transport optimally minimize non-productive time

- Common parts strategy and spare parts management for low life cycle costs

- User-friendliness (easily accessible machining area) offers faster tool setup, safe operation and the option of compact alternative layouts

- High energy efficiency for lower energy costs

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Industry 4.0

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

300 mm

12 in

Workpiece length, max.

250 mm

10 in

Chuck dia., max.

400 mm

15.5 in

| Workpiece dia., max. | mm in | 300 12 |

| Workpiece length, max. | mm in | 250 10 |

| Chuck dia., max. | mm in | 400 15.5 |

| Swing diameter | mm in | 420 16.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact