Universal Cylindrical Grinding Machines

WPG 7

- Workpiece length, max.: 250 mm | 10 in

- Center height: 100 mm | 4 in

- Center length: 380 mm | 15 in

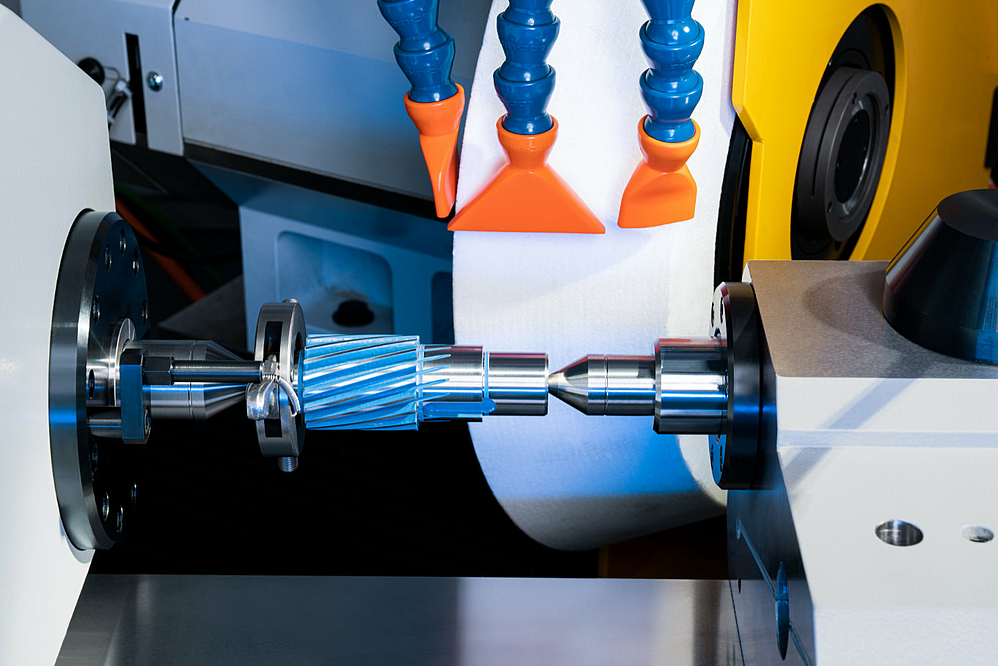

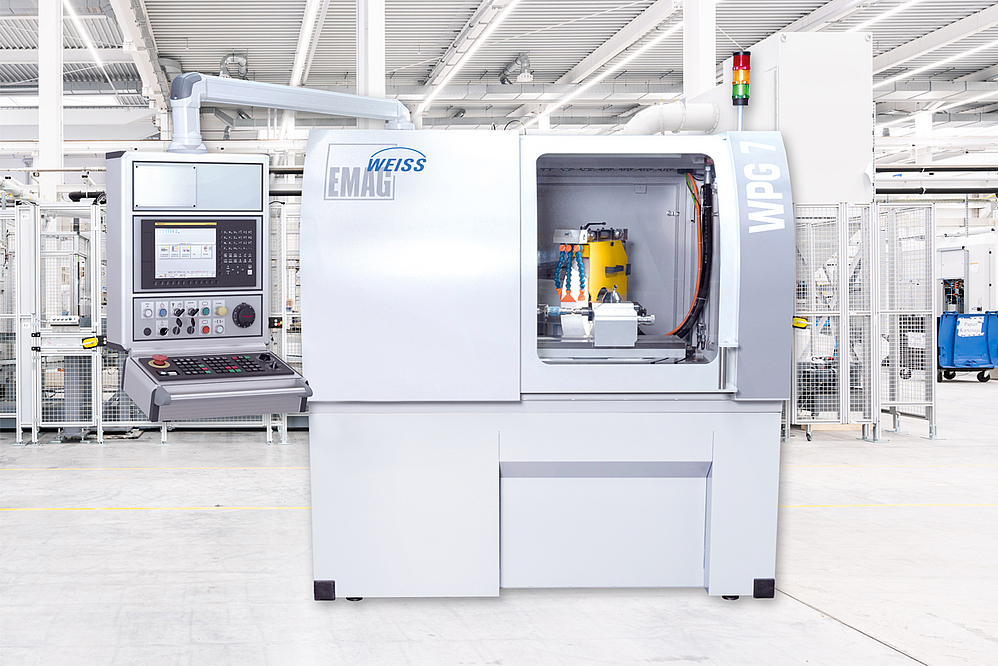

WPG 7 from EMAG WEISS: High-precision external cylindrical grinding with a minimal footprint

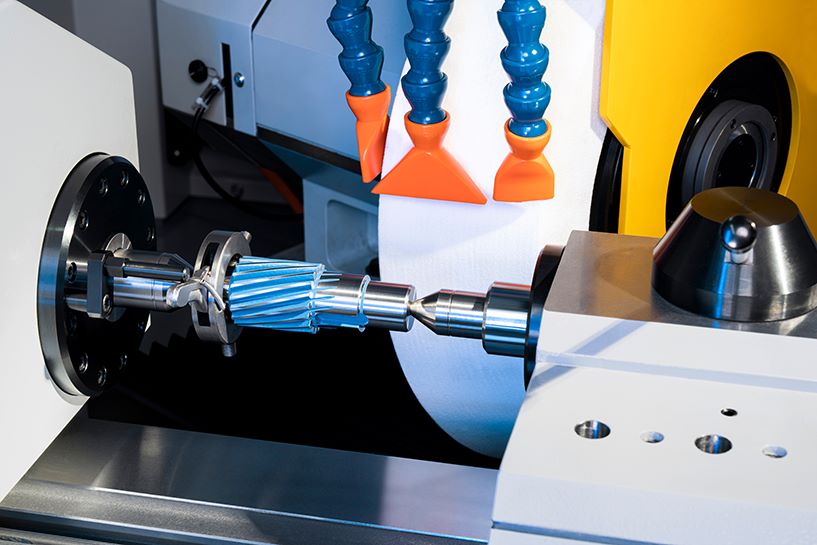

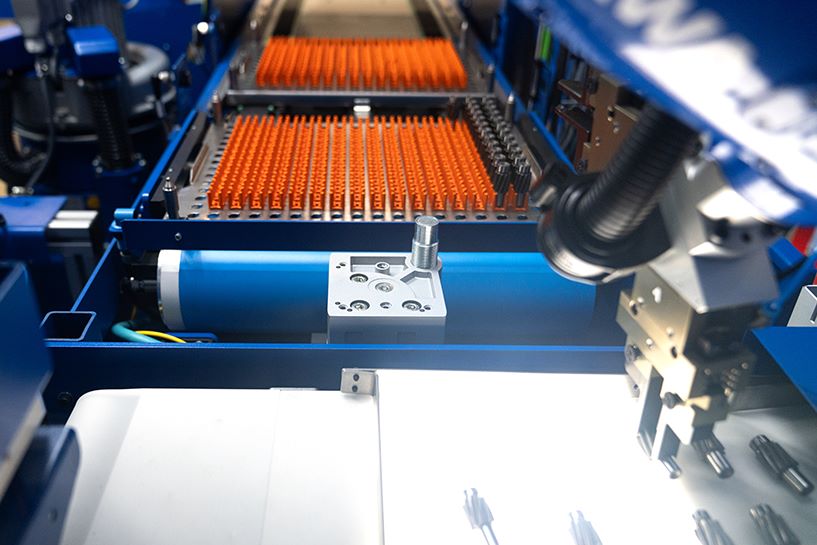

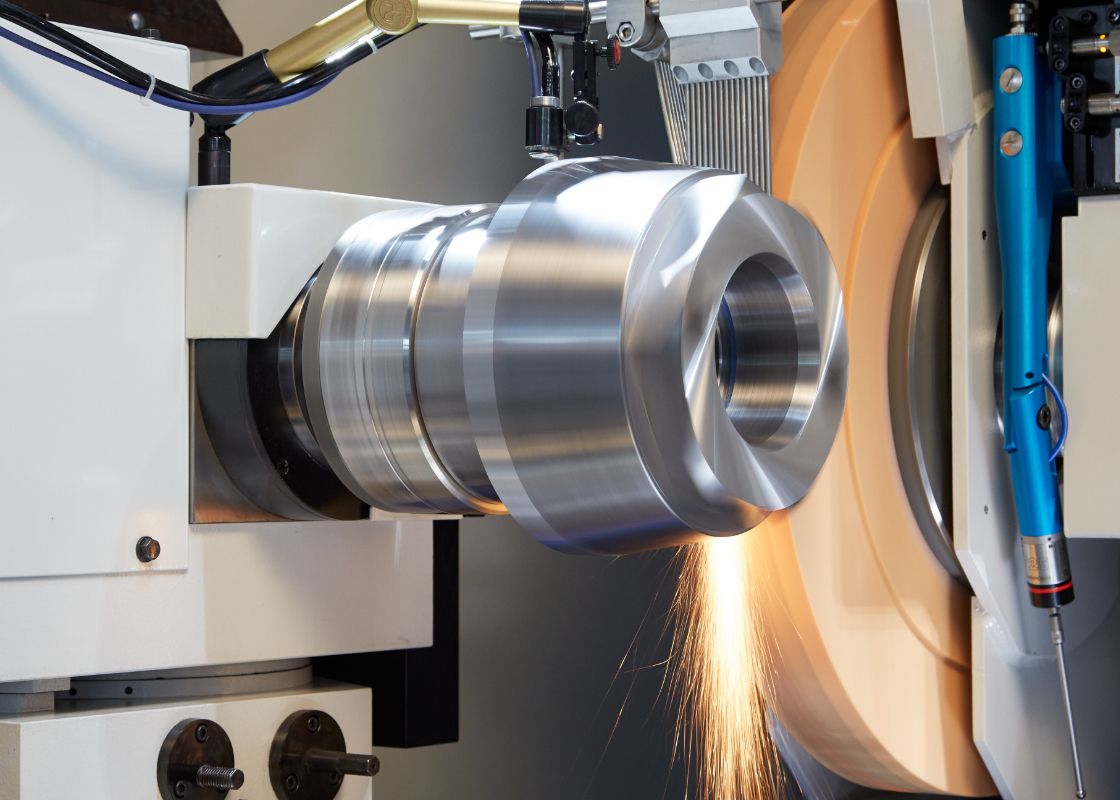

External cylindrical grinding at the highest level and on the smallest footprint: The WPG 7 from EMAG WEISS ensures perfect cylindrical grinding in many applications. High-tech components guarantee precision in the µm range.

The Solution for Perfect Grinding Processes

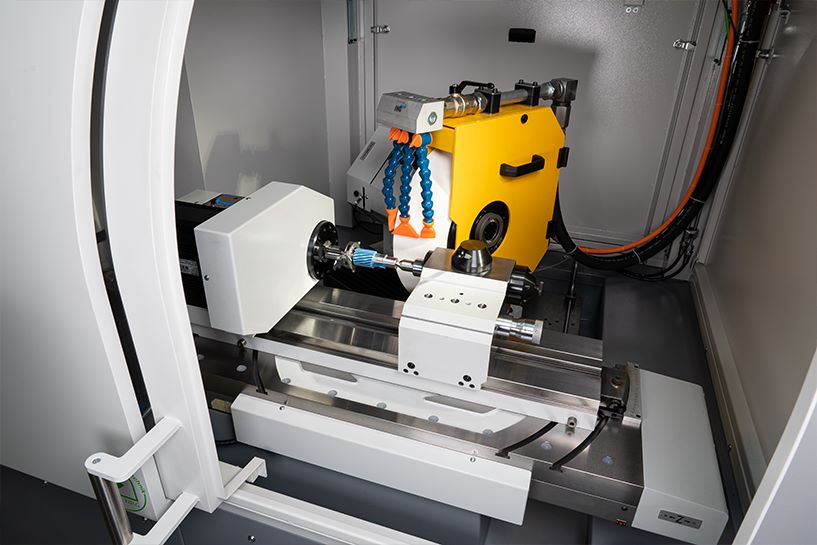

With the WPG 7 from EMAG Weiss, the machining of workpieces up to a length of 250 mm and a maximum diameter of 200 mm is efficient every step of the way.

This is thanks to a rigid machine concept, very dynamic axes, a powerful grinding wheel drive, and a very small footprint. All in all, the WPG 7 only needs around four square meters' space. The robust machine is also highly accessible and can quickly be re-tooled for changing machining tasks.

High-end CNC control

At CNC-Technik Weiss GmbH, we have always put our trust in the expertise of Eckelmann AG for our CNC control solutions.

Even before 1980, Eckelmann started to develop a CNC control specifically for cylindrical grinding. Today, these control units offer functions tailored specifically for grinding, and are still far ahead of the products of other controller manufacturers. Currently, we use the Eckelmann ENC66 controller in all CNC machines.

Advantages WPG 7

- Available as a 0° straight stitch or 30° diagonal stitch machine

- High-speed grinding wheel drive up to 50 m/s

- Grinding wheel diameter with max. 500 x 80 mm

- CBN or corundum wheels can be used

- Fanuc control

- Cooling system with water or oil

- Minimum footprint of only 1,800 x 2,400 mm

- With stationary and moving tip MK4/MK5 or W20/W25

- Optional in-process measurement control (diameter), passive longitudinal positioning, automatic balancing system as well as GAP and crash control

- All common grinding cycles integrated in the control system

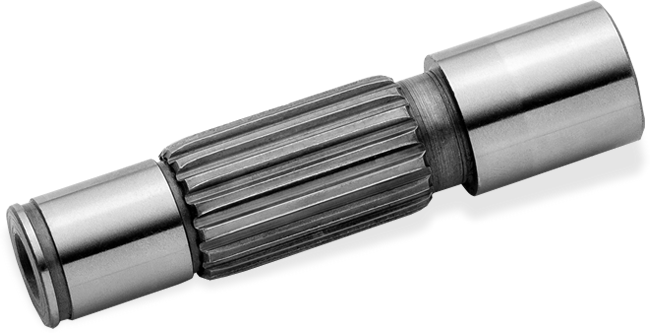

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Technical Data

Workpiece length, max.

250 mm

10 in

Center height

100 mm

4 in

Center length

380 mm

15 in

| Workpiece length, max. | mm in | 250 10 |

| Center height | mm in | 100 4 |

| Center length | mm in | 380 15 |

| Workpiece weight, max. | kg lb | 30 66 |

| Oscillating circuit, max. | mm in | 200 8 |

| Grindable diameter | mm in | 80 3 |

| Axis (Z) Longitudinal travel | mm in | 390 15.5 |

| Axis (Z) Feedrate | m/min ipm | 10 394 |

| Axis (Z) Table adjustment | degrees | 10 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact