White Paper Electromobility

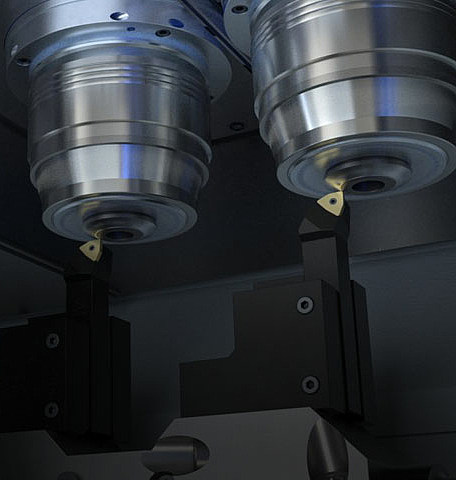

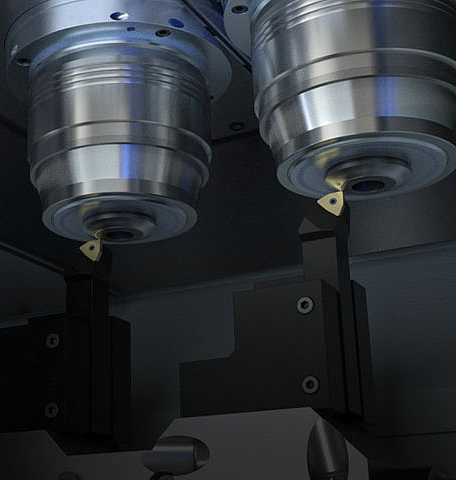

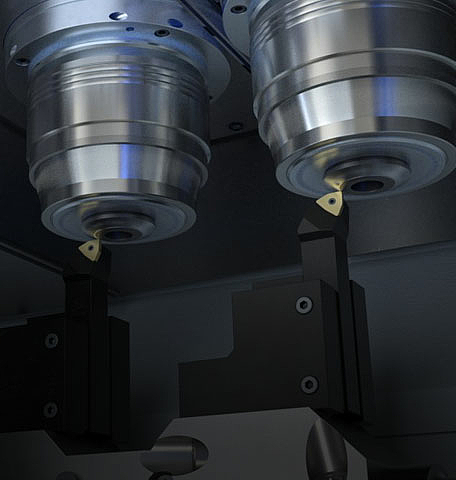

Manufacturing solutions for rotor shafts, sheet metal packages, stator housings and much more

According to a study by McKinsey, up to 75 percent of newly registered cars in Europe should have an electric motor as early as 2030. For car construction, this means: The value-added share of internal combustion engine components is falling.

The proportion of “electrical” components such as batteries, electric motors and power electronics is increasing sharply. They are likely to make up around half of the automotive market in 2030. This includes, for example, many rotation-symmetric parts for which specialists like EMAG already have tailor-made production solutions.

EMAG brings know-how to the establishment of new production solutions for electric motor shafts, stator housings, e-gears and the like. In the end, the customer has an all-round perfect production system that sets benchmarks with regard to cycle times, but at the same time has a high level of stability and process reliability.

Learn in this white paper how highly efficient production solutions for rotors, stator housings and gear parts can look like.

Videos & downloads

You might also be interested in ...

Registration Media Center