After Sales & Service: Maximizing machine availability through strategic service solutions

Unplanned machine downtime is one of the biggest risks in production. Not only does it cause high costs, but in serious cases it can also disrupt the entire supply chain. Maximizing the availability of your production systems is key to securing a competitive edge.

In our recorded webinar we show you how you can ensure the long-term operational reliability of your EMAG machines with a systematic service approach. As a machine manufacturer with extensive experience in after sales and service, we offer you proven concepts that are specifically designed for maximum availability and predictable maintenance.

Here's what you can expect:

- Preventive maintenance concepts: How structured condition analysis contributes to early fault detection

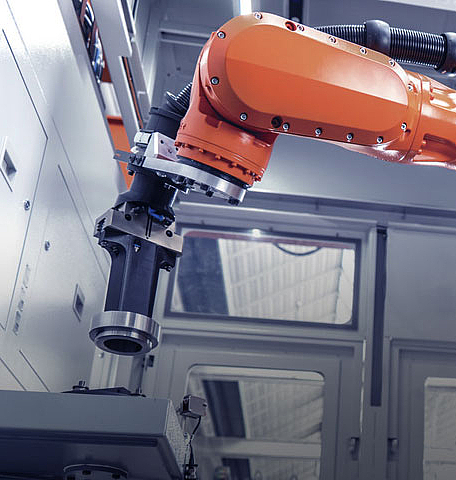

- Spindle repair according to OEM standards: Modular design, economical, and with clearly defined throughput times

- Replacement assemblies: Fast recommissioning thanks to prepared components

- Service contracts: Planning reliability through clearly defined services and costs

- Qualification: Targeted training courses to strengthen maintenance and operating skills

Watch this to find out about proven service approaches in a compact format – with direct practical relevance and specific application examples.

Puede que también le interese ...

Registro en el Centro de Prensa