02/15/2023 - Oliver Hagenlocher - Press

TrackMotion, Robots and Co.: How Suppliers and Contract Manufactures Benefit from Lean Automation Solutions

There are many reasons for using automation and robotics in the manufacturing industry, ranging from compensating for a lack of manpower and simplifying production processes to reducing unit production costs. The latest generation of solutions makes it easier than ever to exploit the advantages of perfectly synchronized production.

It is precisely for this reason that the importance of automation is currently increasing in contract manufacturing and specifically among medium-sized supplier companies. But how can you develop custom-fit and cost-effective solutions for your own production tasks? One answer is provided by the machine builders at EMAG. Their automation solutions come from a trusted, single source and are precisely adapted to the customer's needs and conditions. As a result, flexible and automated processes ensure that, on the one hand, costs are reduced while component quality and process reliability are increased at the same time.

Images

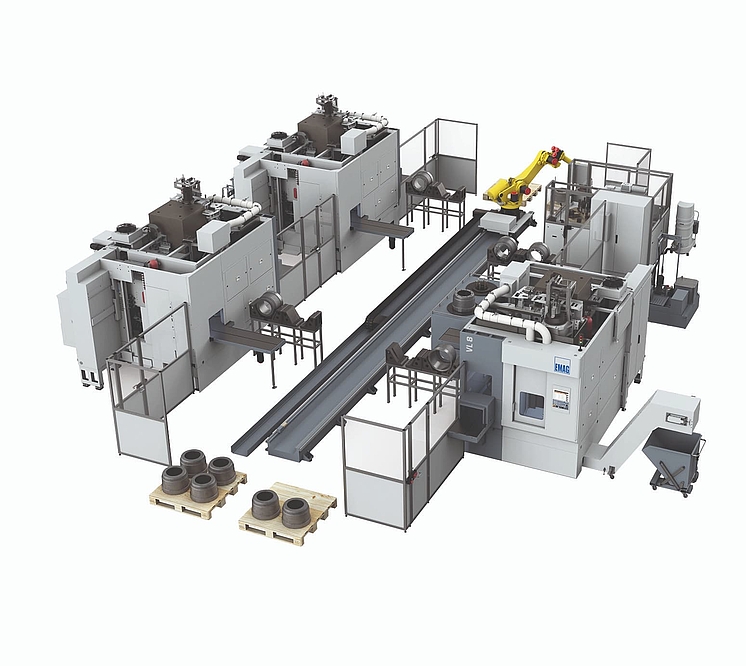

The company Pucktechnik in Solbiate Arno near Milan, Italy, shows how this can be illustrated in concrete terms. The contract manufacturer was founded in 2017 and currently produces casting tools and various components. In total, the company has nearly 30 machines - including eleven EMAG VL Turning machines and a K160L Hobbing machine from EMAG Koepfer. These EMAG solutions provide high-volume and automated series production. Primarily with the help of these EMAG machines, around 650,000 Wheels and Wheel Hubs for earth moving equipment are currently produced by Pucktechnik each year. What is interesting here is that four independent production lines with a high degree of automation are used. The machines in each line are completely interlinked via TrackMotion, also from EMAG, with various operations running directly one after the other. As a result, the quantities produced in this area have increased massively in just a few years. Their success is based on a typical EMAG approach: Vertical machining, assuring the highest possible productivity in the smallest (possible) footprint. This is what the VL machines, used here in combination with TrackMotion automation exemplifies. The basic technological principle of the lines is always the same (regardless of the specific machine type):

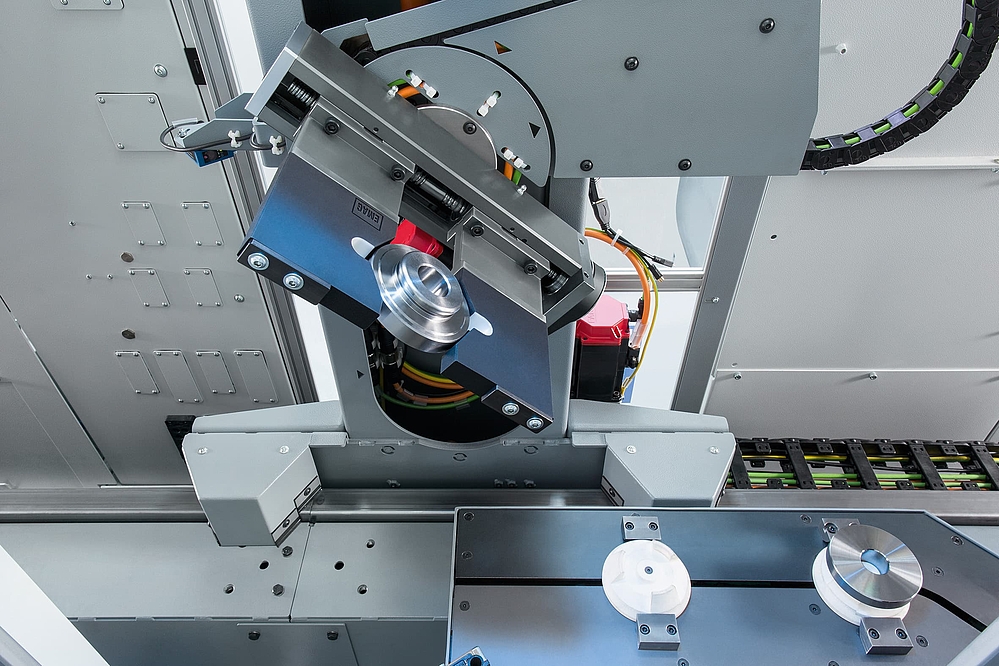

- The TransLift - a lift-and-turn carriage on the TrackMotion line gantry with programmable electric gripper - picks up the raw-parts from a parts store, transports them to the machine at a speed of up to 150 meters per minute and deposits them on the machine's internal shuttle.

- Thanks to the vertical arrangement of the spindle, it can pick up the part from the pick-up position of the shuttle and guide it into the working area of the machine.

- After machining, the workpiece is discharged from the machine via the shuttle and transported to the next machine or the discharge conveyor using the TrackMotion system. If necessary, the TransLift can also turn the component.

TrackMotion: Flexibly configurable

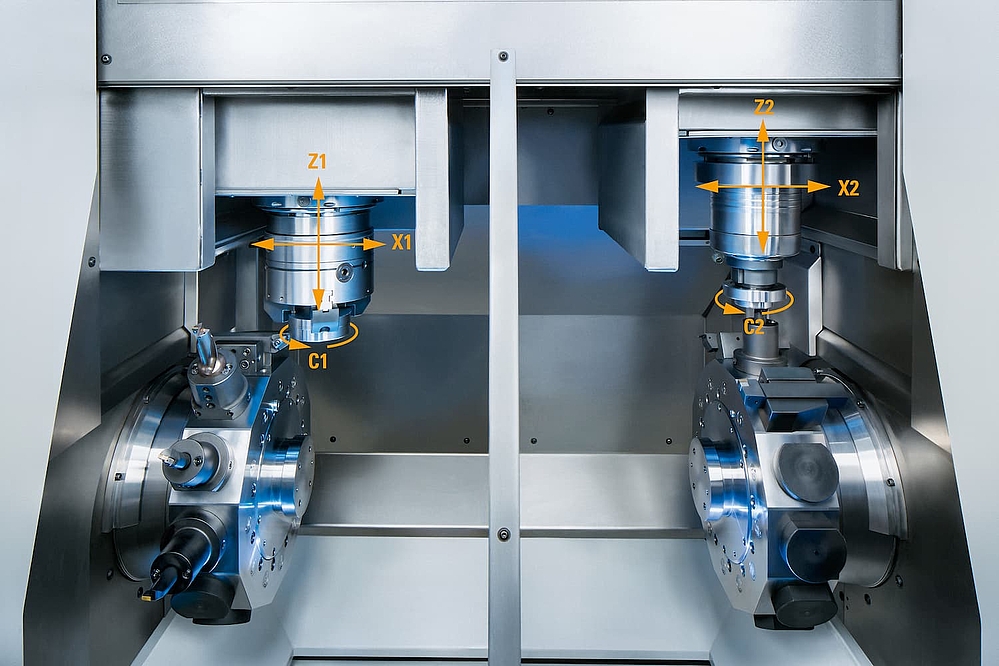

On this basis, a wide range of possibilities opens up with the various EMAG machine types. For example, a VL 3 DUO, which has two completely self-sufficient spindles in separate machining areas for OP 10 and OP 20, can be expanded into a powerful complete system. The TrackMotion automation system not only ensures fast parts transport between the parts storage and work areas, but also turns the components between OP 10 and OP 20. On the other hand, "large solutions" are also possible via TrackMotion - for the production of differential housings, for example. Four machines are used here: In OP 10 and OP 20, both sides of the housing are turned on a vertical VL 4 lathe. For machining the outside in OP 30, EMAG relies on the VT 4, which enables 4-axis machining of the complete outside in one setup. In OP 40, another vertical lathe is used, this time a VL 6.

Robot cells: Increasingly interesting for contract manufacturers

The requirements of the workpiece and the associated production process are also the focus of the developers of EMAG's robot solutions. Critical questions are, for example, what batch sizes are to be produced in a given period of time and how autonomously is the solution to operate. At the same time, the connection of the machines based on pick-up technology is particularly simple. The robot places the part on a workpiece carrier on the machine shuttle, where the internal automation takes over as described. The components are fed into the robotic cell, for example, by infeed and outfeed conveyors, palletizers, drawers or by bin picking, with each solution having different strengths and basic conditions. The possibilities opened up by this approach are shown, for example, by the combination of two VL 3 DUOs with a robot: First, two components are simultaneously machined from one side in the first machine. Then the robot picks them up, turns them and feeds them to the machine for simultaneous machining of the second side, resulting overall in high output quantities in short periods of time. In addition, the cell can be easily adapted to other processes. The "truck drum brake" example is also interesting: here, four VL 8 machines are linked-up by means of a robot on an additional travel axis - a concept that combines the flexibility of a robot with the reach of a gantry.

In summary, the combination of EMAG pick-up technology with various automation solutions from TrackMotion to robots results in extremely powerful and individually adaptable systems. New machines can be integrated into the process at any time. Contract manufacturers and subcontractors in particular benefit from this: They produce parts faster, more error-free and more cost-effectively - from gears to shafts and wheel hubs to differential housings and many other components.

Contact