Precision Manufacturing in E-Mobility – Cost Effective Production of Rotor Shafts and Gears

As e-mobility production volumes continue to grow, so do the demands for production efficiency and the quality of key components such as rotor shafts. We cordially invite you to watch this recorded webinar, where we will present reliable, cost-effective solutions for manufacturing these complex components.

Focus of the webinar:

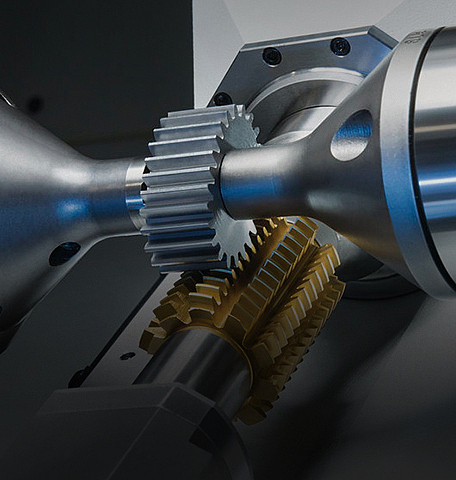

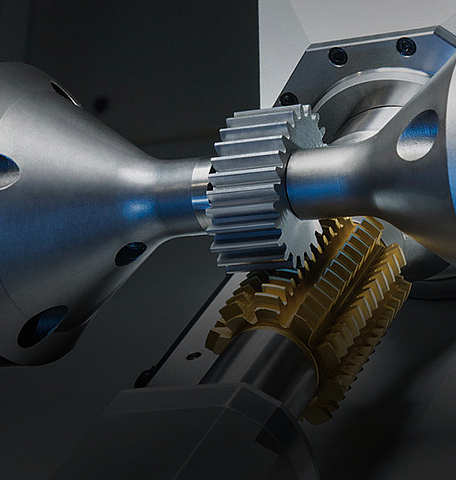

1. High-precision machining of rotor shafts for electric drives

- Technology solutions for precision gear cutting with cycle times under 35 seconds

- Process for achieving top-tier surface finishes for low-noise operation

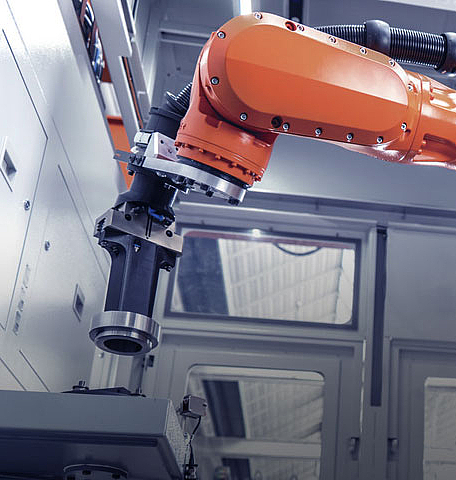

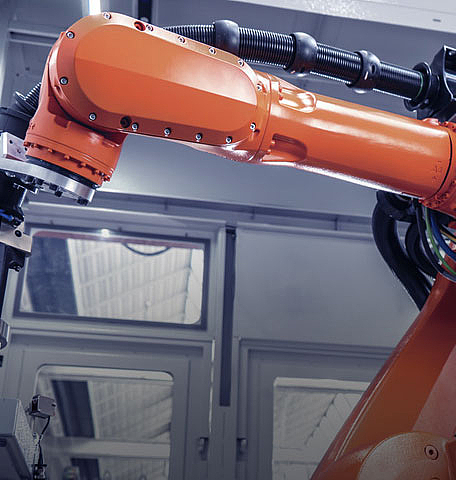

- Complete-machining of assembled and one-piece rotor shafts

2. Efficient process chains for assembled rotor shafts

- Integration of joining, preheating and welding processes

- Precision laser processing with minimal component distortion

- In-process measurement and quality assurance solutions

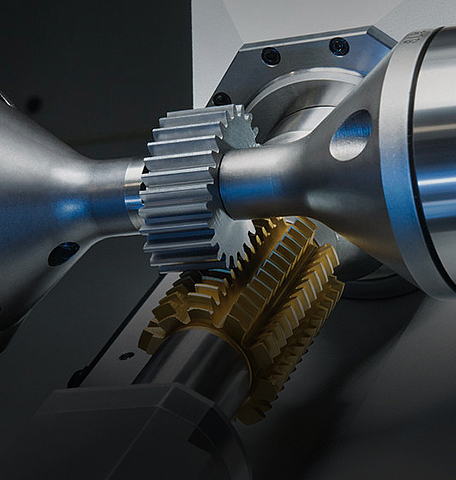

3. Combined machining processes for gears and flange parts

- Turning and grinding processes on one platform for maximum efficiency

- Machining of internal and external gears in a single setup, power skiving as a key technology

- Practical examples of optimized high-volume production processes

The manufacturing solutions showcased are ideal for companies scaling up production while maintaining the highest quality standards. We demonstrate how to reduce your cycle times, streamline machining processes and boost overall production efficiency.

Videos & downloads

You might also be interested in ...

Registration Media Center