Manufacturing high-precision pump components - Grinding solutions from EMAG for greater efficiency

Pumps are not only an essential part of our daily lives, but also a key component that makes a decisive contribution to increasing efficiency in many areas. As they become more widespread, the demands on quality, efficiency and reliability are also increasing.

Out-of-round geometries are indispensable for many pumps. On the one hand, the special design ensures a uniform volume flow in the hydraulic system (which is largely irrespective of the system pressure). On the other hand, it also ensures low running noise and a generally high level of efficiency. To achieve these properties, a grinding process is essential. In this webinar we present current solutions and application examples for grinding pump components.

In this webinar you will learn:

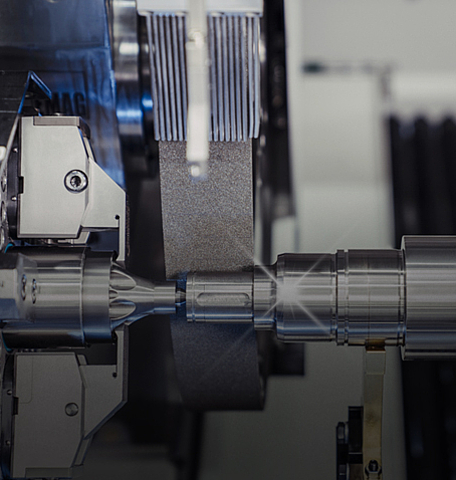

- Focus on precision: How EMAG grinding machines enable precision in the micrometer range for out-of-round surfaces.

- Technical insights: Details about the grinding process, which is crucial for a smooth volume flow and minimal operating noise.

- Practical examples: Insights into the machining of cam rings, rotors, stators and pump rings with EMAG machines.

- Flexibility and speed: The advantages of flexible and fast machining of a wide range of workpieces.

This recorded webinar is essential for anyone who wants to optimize their production processes and keep up to date with the latest designs and developments in the manufacture of piston rods.

You might also be interested in ...

Registration Media Center