Why the coordination of laser metal deposition and grinding is crucial for the quality of coated brake discs!

The Euro 7 standard sets significantly stricter limits for the abrasion of tires and brake systems. In order to achieve this radical reduction from the current level of up to 40 milligrams of particulate matter per kilometer to just around three milligrams from 2035, designers and developers in the automotive industry are increasingly focusing on the coating of brake discs.

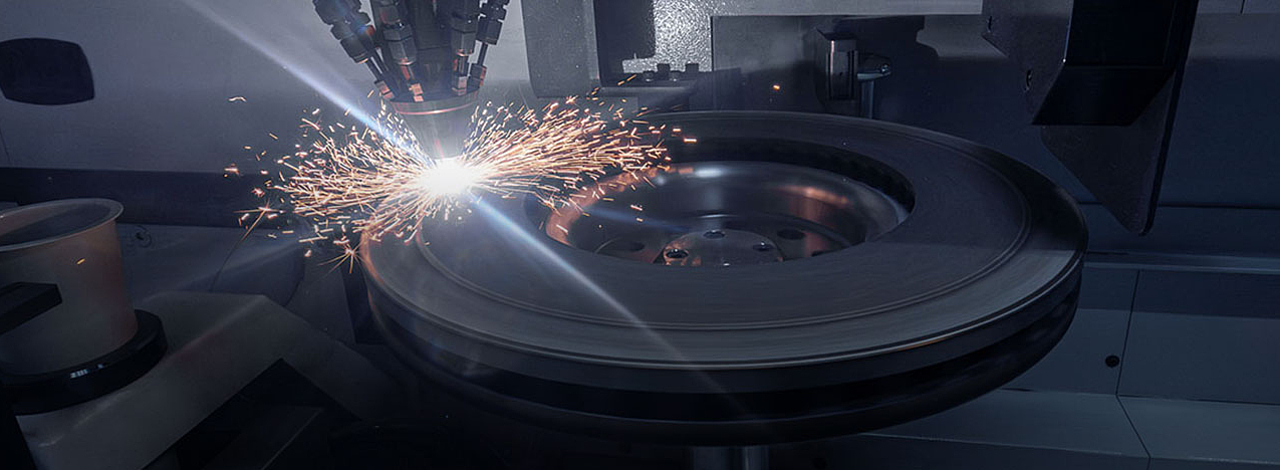

In this recorded webinar, we will shed light on EMAG's laser coating process and show how this approach can be integrated into a holistic and high-volume production solution - including the subsequent grinding processes that give the brake disc its final surface.

Topics of the webinar:

- The Euro 7 standard: overview of the new limit values and their significance for the automotive industry.

- The EMAG laser coating process: Detailed presentation of the process and its advantages.

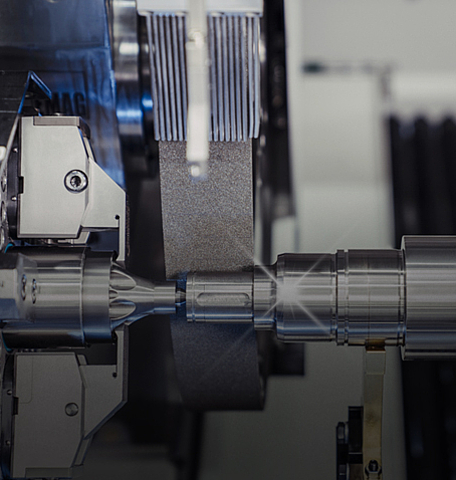

- The sanding process: choice of abrasive, elasticity of the workpiece and other decisive factors for productivity.

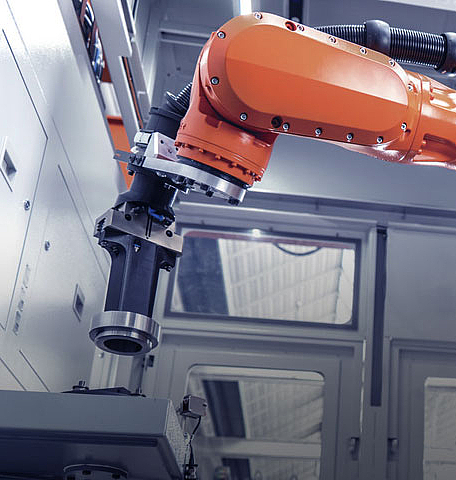

- Holistic production solutions: Integration of laser metal deposition and grinding into an efficient process chain.

- Expert knowledge: Importance of collaboration between grinding, coating and laser experts.

Find out how you can meet the requirements of the Euro 7 standard and at the same time increase the quality and efficiency of your production processes.

Videos & downloads

You might also be interested in ...

Registration Media Center