Vertical Turning and Grinding Centers, Shafts

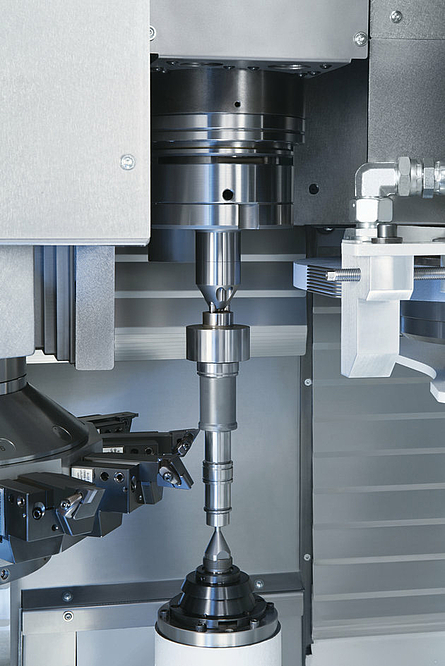

VTC 100 GT

- Workpiece dia., max.: 100 mm | 4 in

- Workpiece length, max.: 400 mm | 15.5 in

- Chuck dia., max.: 210 mm | 8.5 in

EMAG VTC-Machines: A Joint “Attack” on Shafts

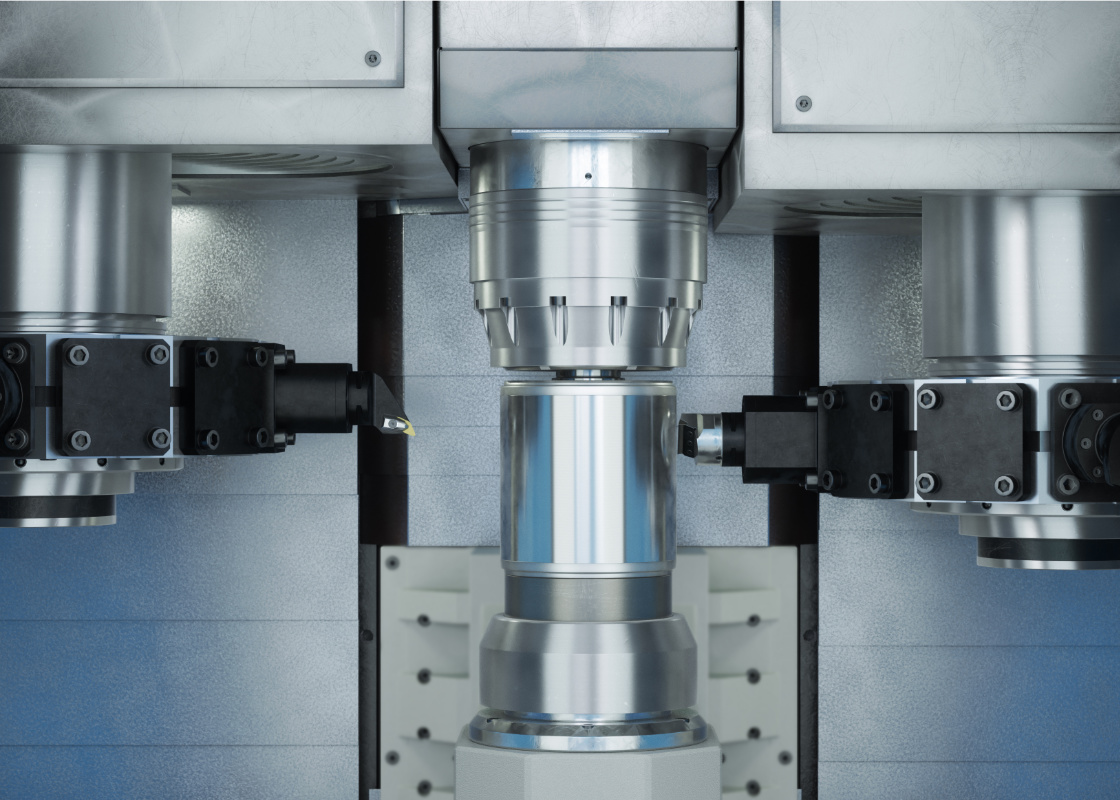

VTC vertical turning and grinding machines from EMAG ensure fast processes when turning and grinding operations come together. More flexibility isn't available; almost the entire finishing process is carried out in the VTC vertical turning and grinding machine. Hard and soft turning, scroll-free turning, grinding and simultaneous grinding, synchronous support grinding and non-circular grinding are all possible on a single machine.

In short: VTC vertical turning and grinding machines guarantee efficient shaft production with reliable processes.

VTC 100 GT - All-Around Solutions for Shafts

The VTC 100 GT turning and grinding machine ensures fast cycles for hard turning and grinding. The tool turret completes all turning operations, while the grinding takes place at a second station. Thus, the VTC 100 GT multi-functional machine is the perfect production tool for the complete machining of cylindrical bearing seats or shoulders and grooves, for example. Machined in a single clamping, true running errors resulting from separate clamping operations are reduced.

Important to note is that the component may be changed at any time. VTC 100 GT machines can be quickly reconfigured for evolving machining tasks. Even complex combination processes can be configured extremely efficiently on the EMAG turning and grinding combination machine.

Advantages VTC 100 GT

- All hard machining processes on a single machine: CBN grinding, hard turning and scroll-free turning

- Integrated loading and unloading: the EMAG tool turret reduces automation and peripheral costs as raw and finished part storage areas form an integral part of the machine

- Complete hard machining of shafts, thus eliminating clamping errors

- Ideal chip flow conditions through the vertical design

- Smaller footprint due to compact, vertical construction

- Short tooling and re-tooling times thanks to excellent accessibility and ease of operation

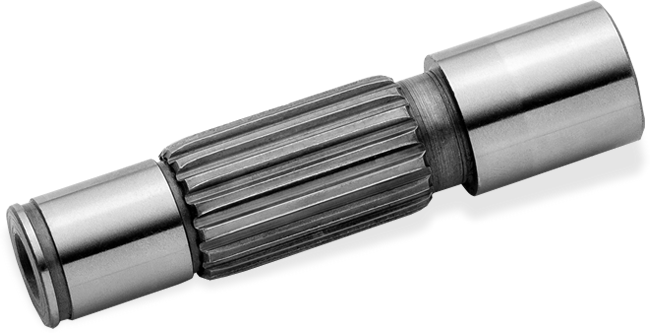

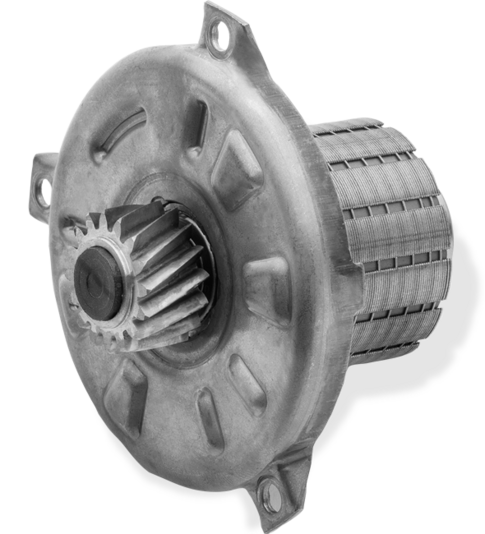

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Grinding, besides drilling, is one of the best known chip removal production methods because it is also frequently used during daily activities.

The combination of a number of processes – such as hard turning and grinding – on a single machine, allows for the exploitation of considerable…

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Technical Data

Workpiece dia., max.

100 mm

4 in

Workpiece length, max.

400 mm

15.5 in

Chuck dia., max.

210 mm

8.5 in

| Workpiece dia., max. | mm in | 100 4 |

| Workpiece length, max. | mm in | 400 15.5 |

| Chuck dia., max. | mm in | 210 8.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact