Innovative Machine Tools and Manufacturing Systems for a Huge Range of Applications

Decades of experience in machining, gear cutting, laser welding and electro-chemical machining go into the development and production of state-of-the-art machine tools from EMAG. The result: cutting-edge manufacturing solutions for a multitude of applications in the aerospace, automotive, off-highway and energy sectors.

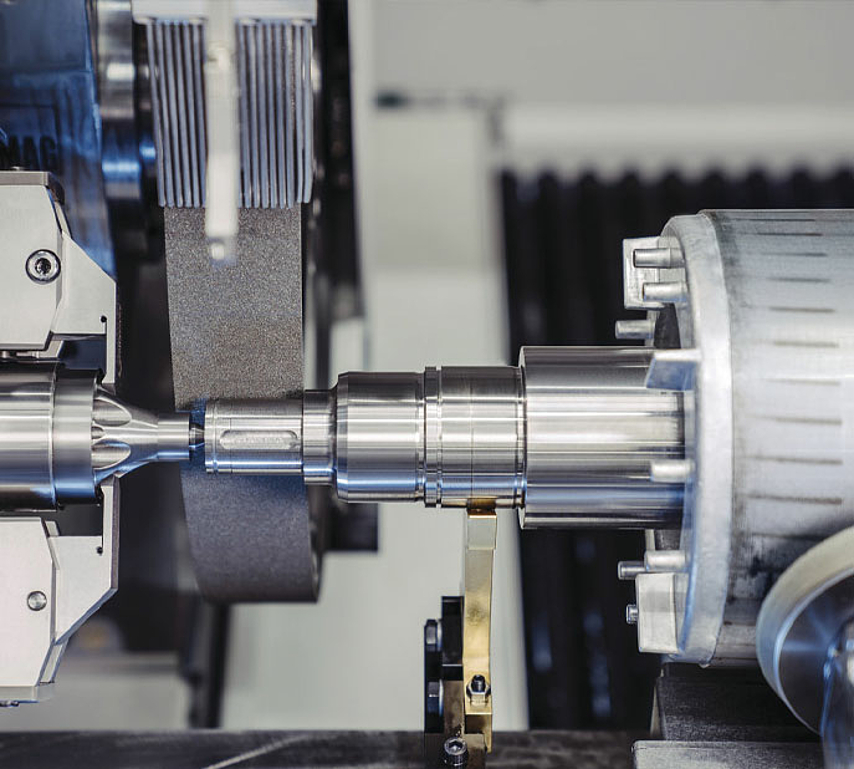

Turning Machines

EMAG is the global market leader for vertical pick-up turning machines. These vertical lathes are ideal for manufacturing large batch sizes of chucked and shaft components. Additionally, integrated automation technology ensures the high productivity of EMAG CNC machines.

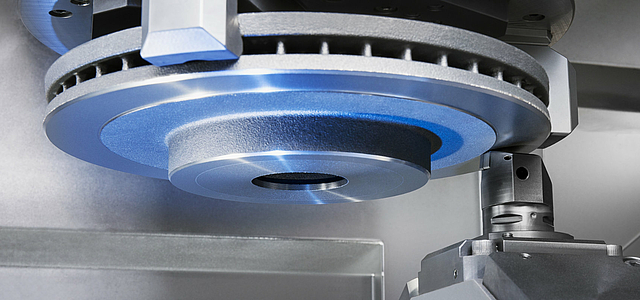

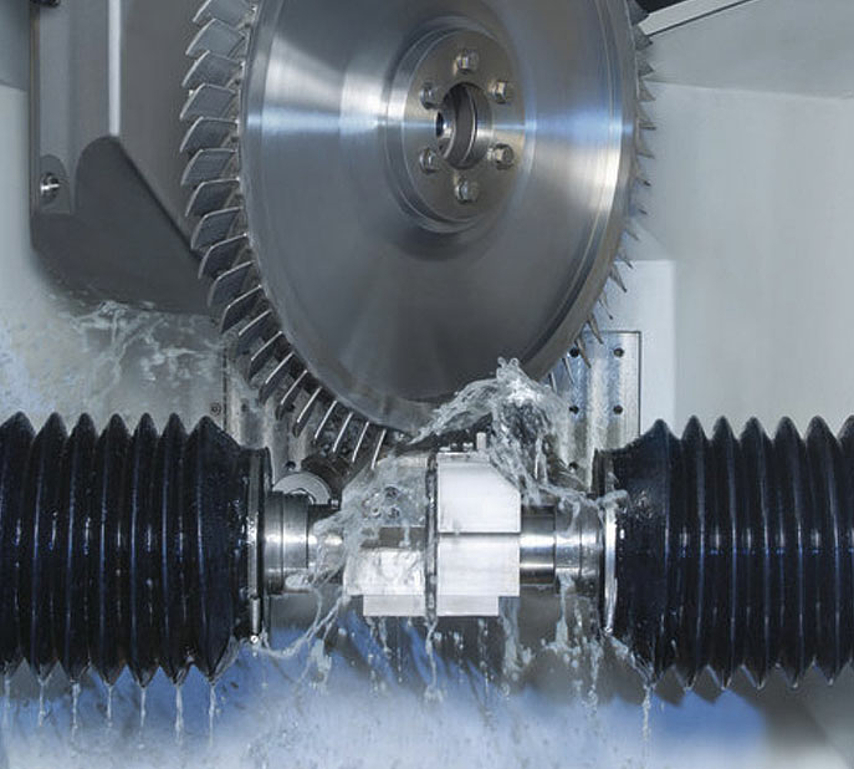

Turning MachinesGrinding Machines

EMAG manufactures grinding machines for a wide range of applications. Whether its internal or external cylindrical grinding, non-round machining for parts such as cams or crankshaft grinding – EMAG provides the right technology!

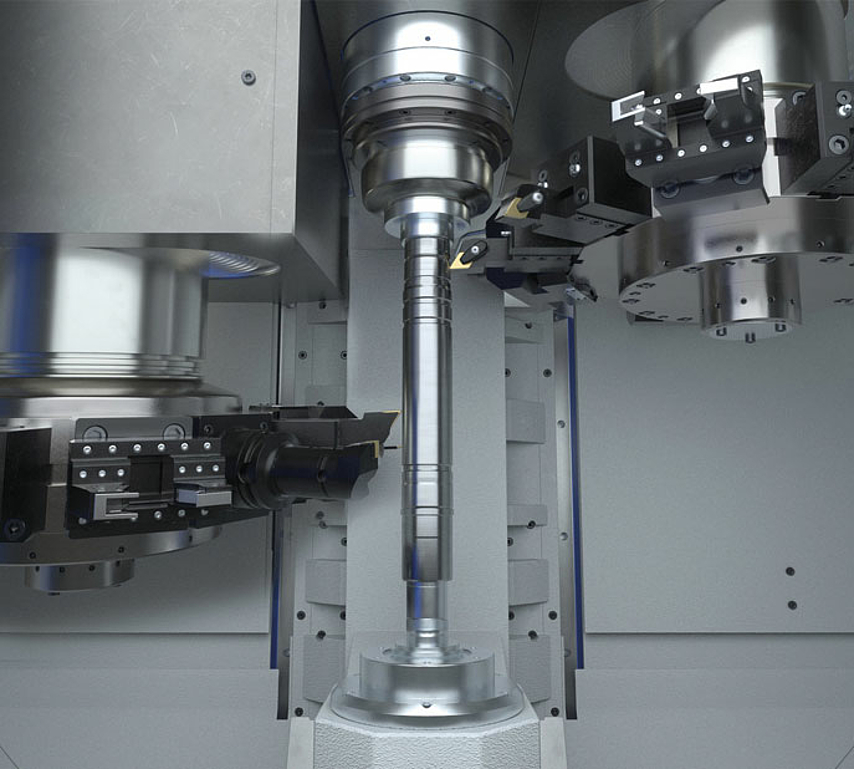

Grinding MachinesMachining Centers and Milling Machines

The vertical machining centers from EMAG are used to machine components with complex geometries and large diameters. The vertical CNC machining centers can be equipped with a multitude of machining technologies and offer the greatest freedom when it comes to flexibility.

The HCM 110 is a dual spindle milling machine for ball cage milling. The machine is designed for both soft and hard milling. Owing to its high precision, this milling machine from EMAG can entirely replace the grinding process for ball cages.

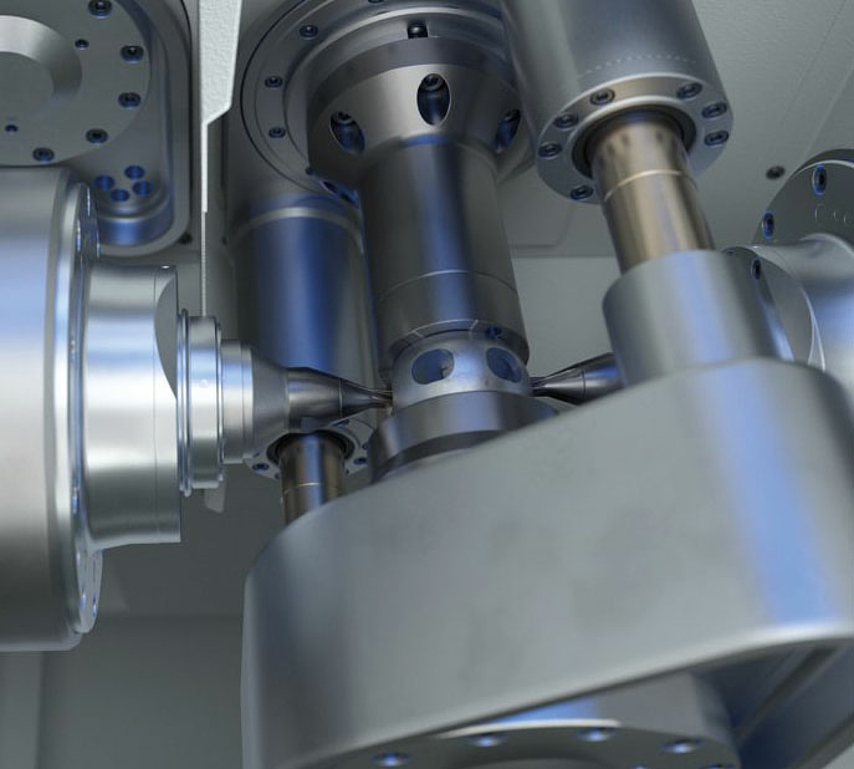

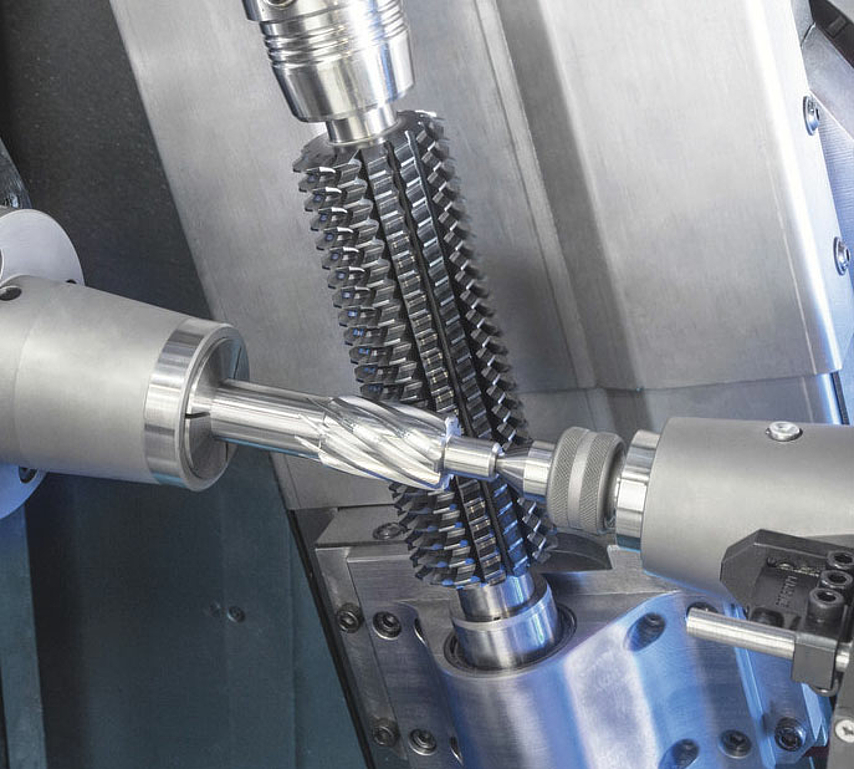

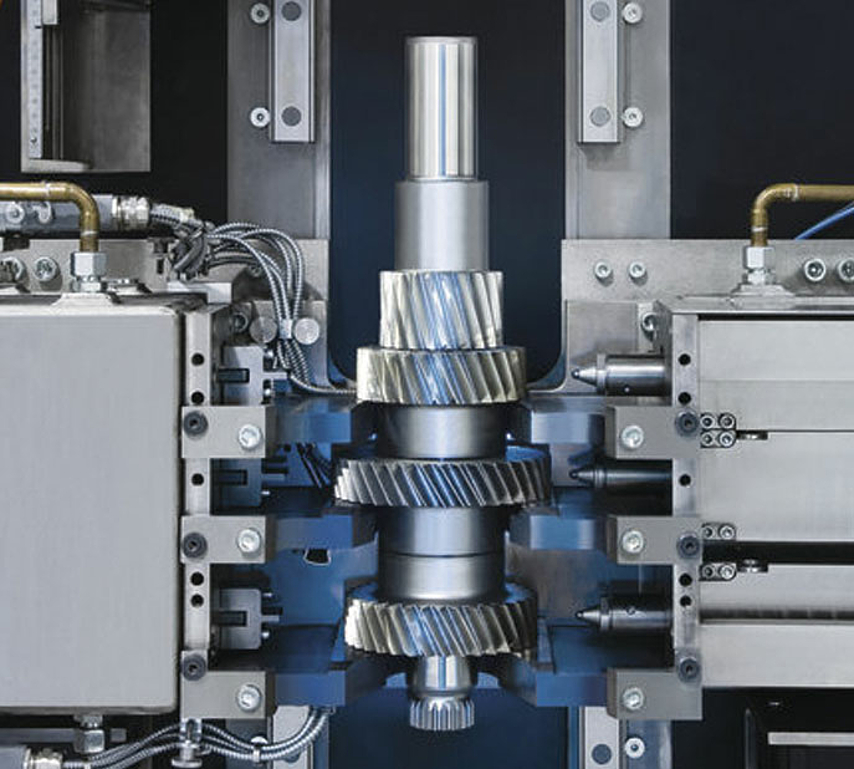

Machining Centers / Milling MachinesGear Cutting Machines

EMAG is known as a supplier of top-quality gear hobbing technology for high-efficiency gear production. EMAG has the right solutions for gear production: cutting-edge gear hobbing technology and the complimentary machines for chamfering and deburring.

With EMAG SU (former Samputensili), EMAG is systematically expanding its scope of technology by adding a range of gear production methods: shaving, shaping, tooth flank grinding, profile grinding and generating grinding.

Gear Cutting MachinesCouplings Machining Centers

EMAG offers customized solutions for the machining of coupling sleeves. EMAG’s modern machine tools cover all threads used in the OCTG sector, including international (API, GOST) and proprietary standard (premium threads).

Couplings Machining CentersLaser Welding Machines

EMAG LaserTec supplies laser welding systems for the production of transmission components of all kinds. Its laser welding systems, and their developed processes, have become industry standards.

Laser Welding MachinesECM / PECM Machines

EMAG ECM provides electrochemical machining (ECM) technology and systems for the production of extremely hard materials and residue-free production of strategic workpieces. Significant productivity gains can be achieved with machines for the production of engine parts, such as blisks.

ECM / PECM MachinesJoining machines

With the joining systems from EMAG, the heat shrink processes achieve stable connections by force fitting alone. For making camshafts or transmission rods or to prepare for laser welding, this joining process is ideal.

Joining machines