The EMAG Inverted Spindle Pick-Up Lathe process provides for a significant improvement in accuracy versus that of a sub-spindle lathe.

Lathes with sub-spindles pass a part from one rigid work holding system to another. This does not allow for any misalignment of the two spindles. The first spindle cannot release a part until the second spindle has a secure grip on it. Allowing for mismatches on a split turned dimension such as a bore. The accuracy and quality of the workpieces that are produced from this system are compromised because of this process.

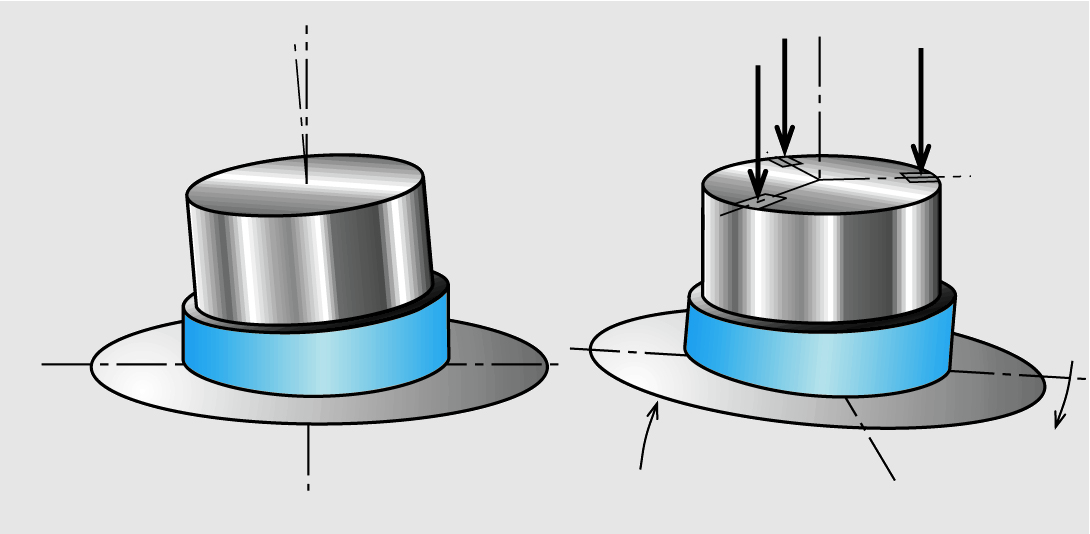

The innovators at EMAG noticed that there was an opportunity for improvement here and created the automatic pick-up lathe. The EMAG pick and place system has the part in a free state on a spring loaded plate which allows the part to sit evenly onto the locating surface. This automated system makes it possible to achieve the highest quality, without the manual labor. With this innovative technology, customers have experienced up to an 80% reduction in the mismatch between split turned surfaces.

To learn how the EMAG Inverted Spindle can improve your production system, visit www.emag.com.